The Magnet Test for Stainless Steel is Not Accurate

The magnet test is NOT a correct way to verify stainless steel.

Stainless steel is a common name for metal alloys that consist of 10.5% or more Chromium (Cr) and more than 50% Iron (Fe). Although it is called “Stainless” a better term for it is “highly stain resistant.” It is a darker metal. There are two process methods to make it bright, both are surface treatments.

There are three major classes of stainless steel.

1. Austenitic: Chromium-nickel-iron alloys with 16%-26% chromium (Cr), 6%-22% nickel (Ni), and low carbon content, with non-magnetic properties. Type 304 ( 18% chromium, 8% nickel ) is the most commonly used grade or composition.

2. Martensitic: Chromium-iron alloys with 10.5%-17% chromium and carefully controlled carbon content. It has magnetic properties! Type 420 is a typical example. It is mostly used in knives and kitchen equipment.

3. Ferritic: Chromium-iron alloys with 17%-27% chromium and low carbon content, with magnetic properties! Type 430 is the most commonly used ferritic.

The chromium content in stainless steel alloys is what generally prevents corrosion. The chromium works by reacting with oxygen to form a tough, adherent, invisible, passive layer of chromium oxide film on the steel surface. If damaged mechanically or chemically this film is self-healing as long as it has enough oxygen. Since oxygen is necessary for the reaction, liquids and other things stored for a prolonged time in stainless can prevent oxygen contact and thus promote corrosion. If you remove rust with a cloth the chromium will chemically react with the oxygen in the air and produce a new protective layer.

An increase in chromium content improves the corrosion resistance of stainless steel. The addition of nickel is used to raise the general corrosion resistance required in more aggressive usage or conditions. The presence of molybdenum (Mo) improves the localized corrosion resistance. Other alloy metals are also used to improve the structure and properties of stainless steel such as Titanium, Vanadium, and Copper. Non-metal additions typically include natural elements such as Carbon and Nitrogen as well as Silicon. The S304 we use to make our stainless casters has 8.07% nickel (Ni) and 18.23% chromium (Cr).

The process of stamping and surface polishing can change the non-magnetic property of S304. The pressure used in stamping and forming changes the distribution of chemicals in the alloy. The stamping dies used can also chemically leave iron ions on the surface of the stainless steel. Both factors can cause change to the non-magnetic property of the stainless and thus create magnetism! Foreign residue can also be corrosive.

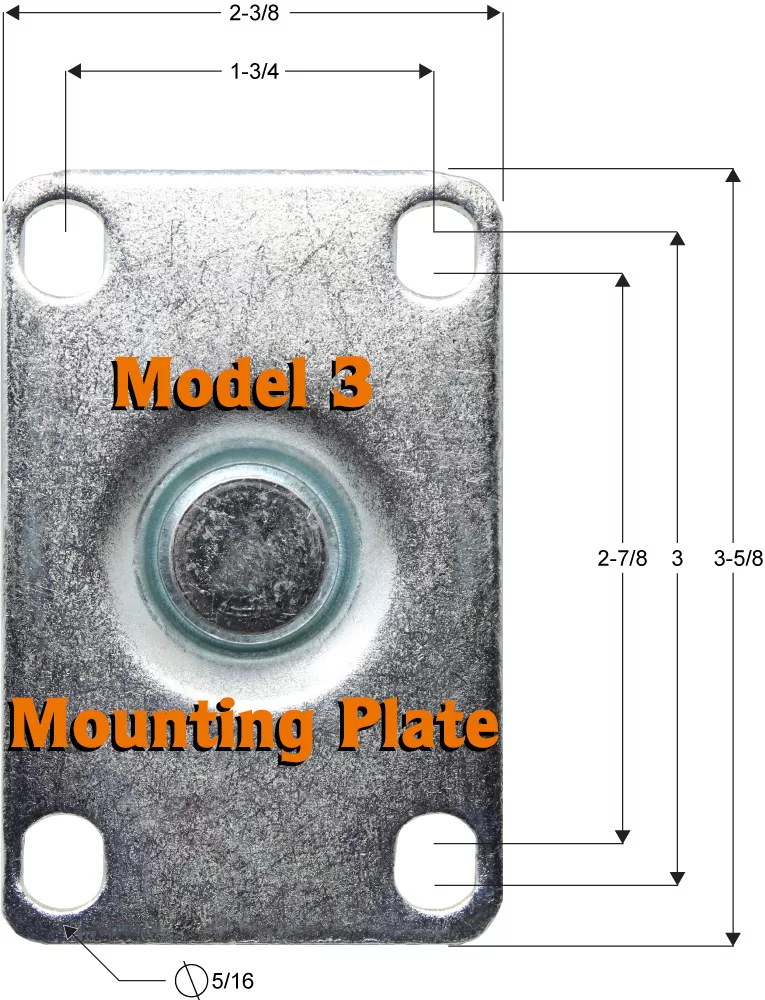

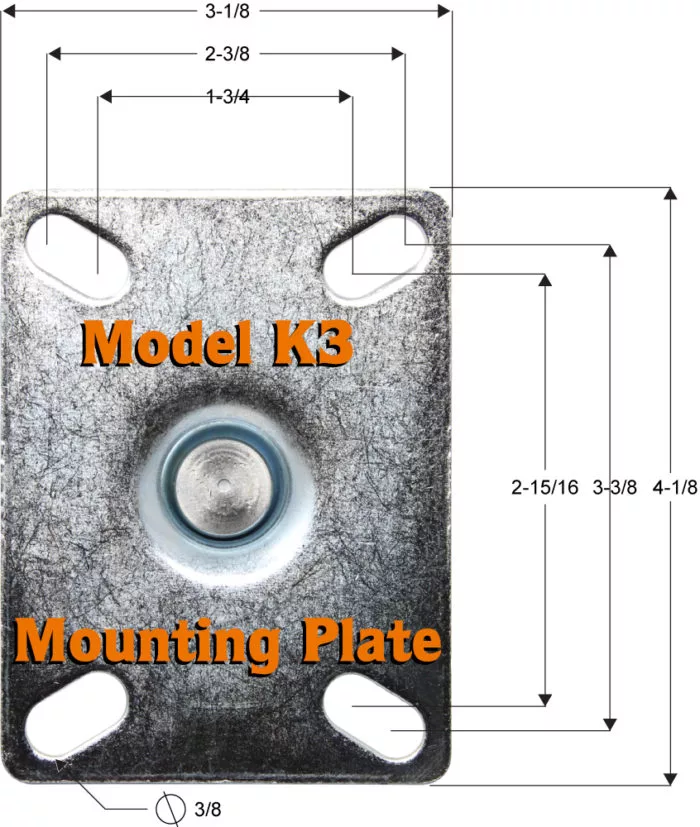

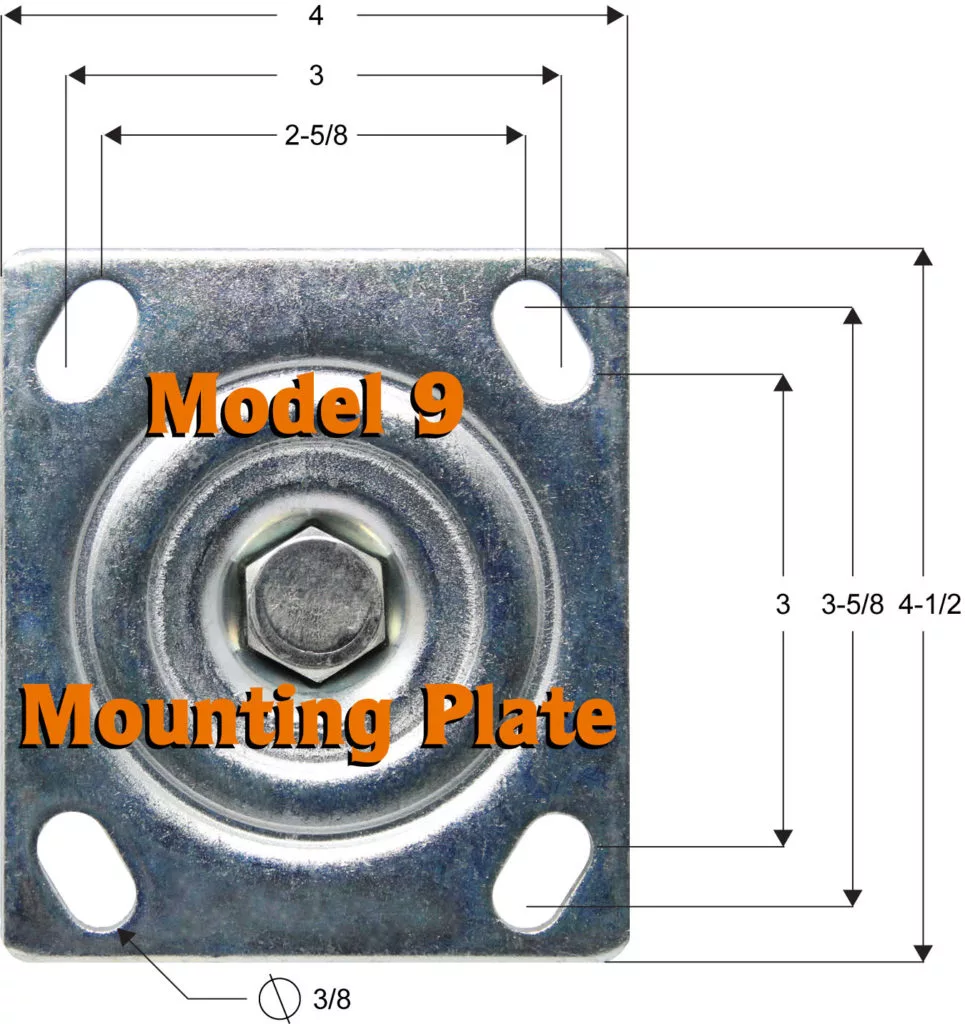

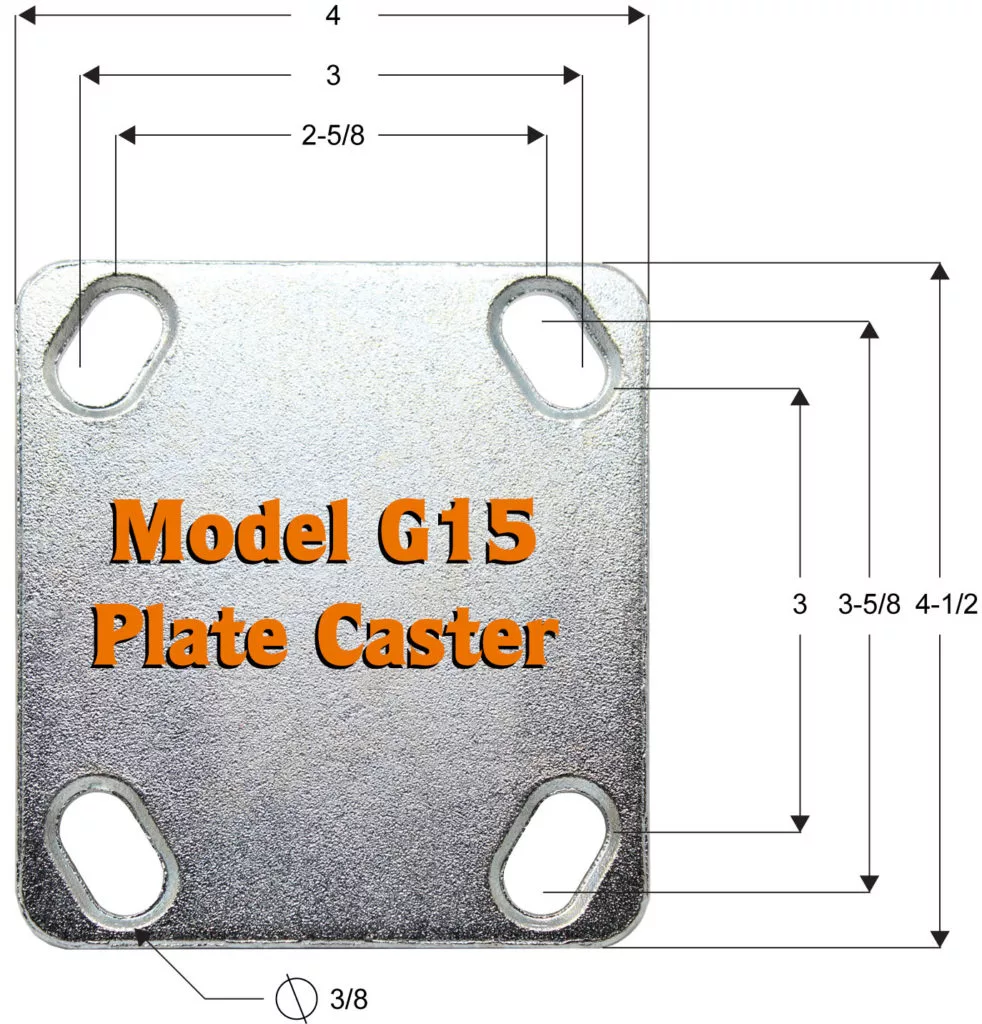

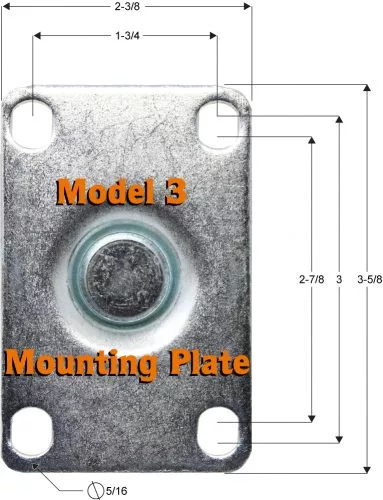

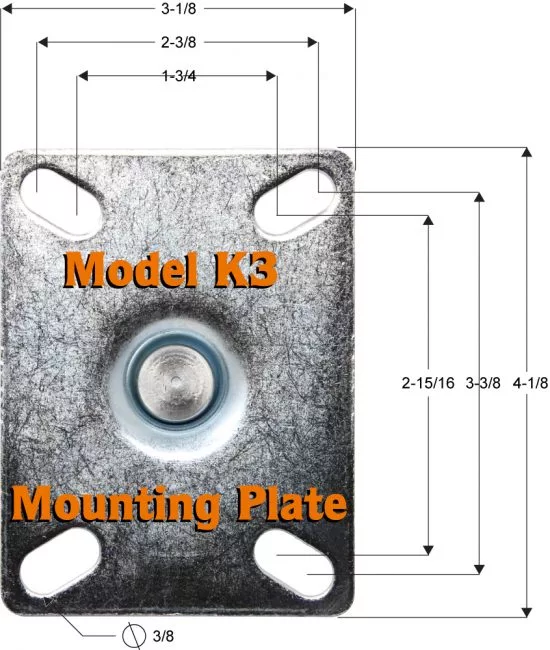

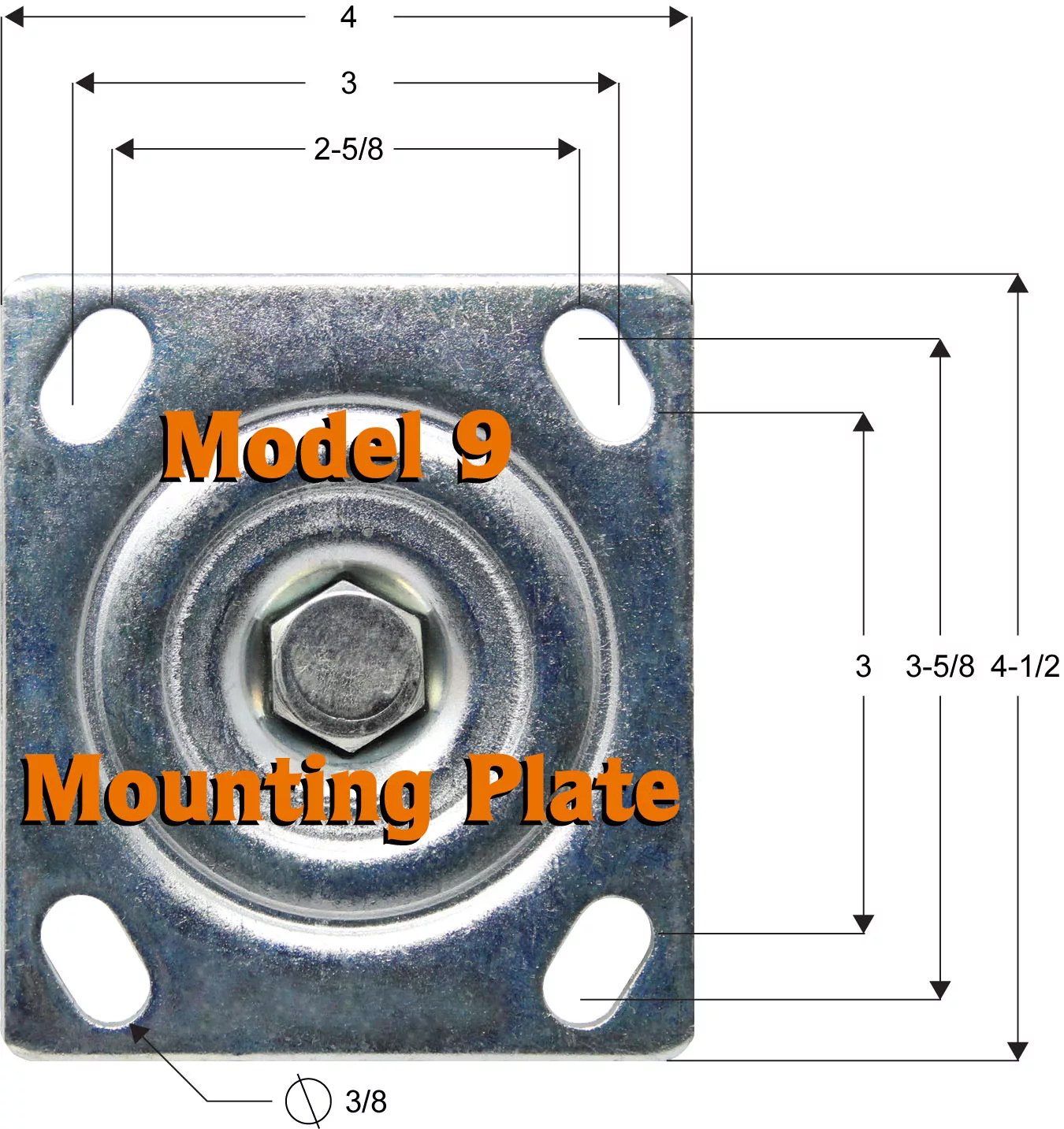

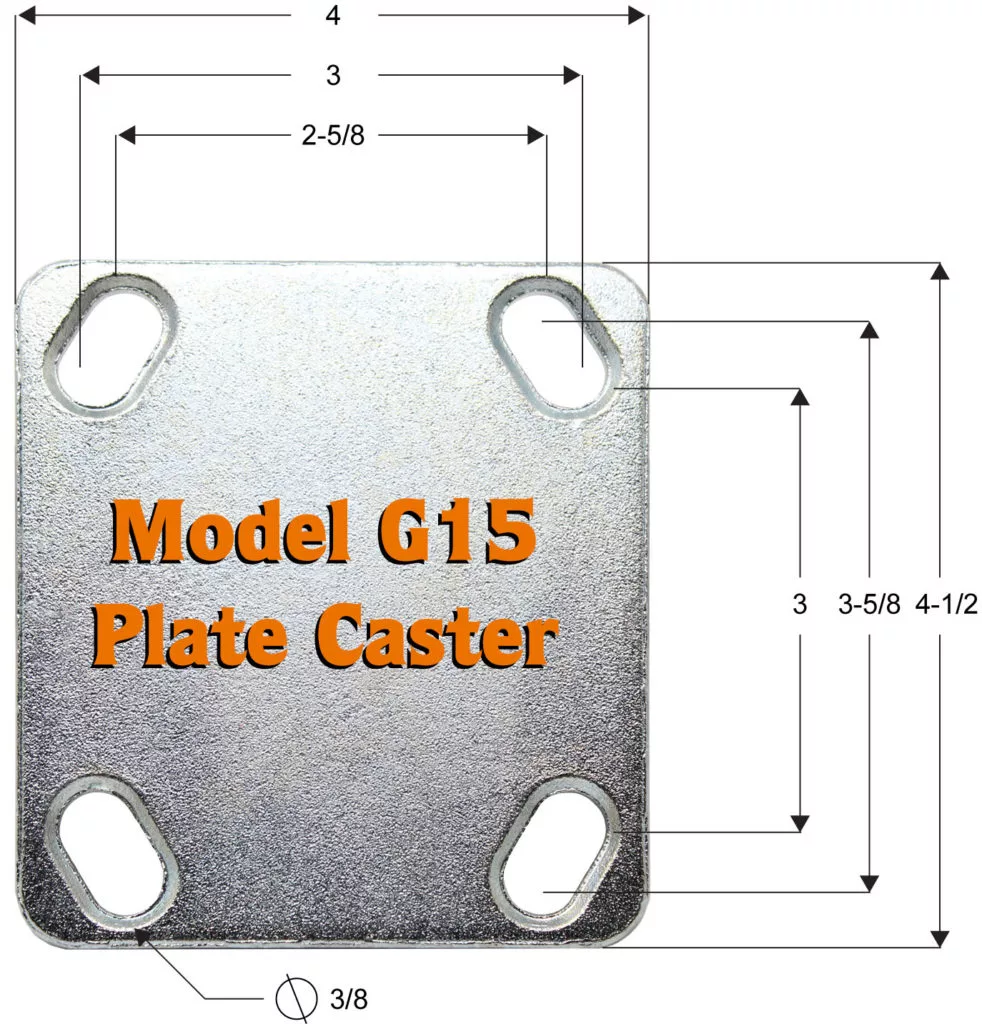

We apply an electro-cleaning surface treatment to our stainless caster models K3, 3, 3A, and 9. It does not necessarily prevent the stainless steel from picking up iron particles as a result of how it is handled or stored. We apply an additional passivation treatment only to our stainless caster model G15 using nitric or mild organic acids to enhance the protective nature of the natural, air-formed film. Nitric acid treatment enhances the level of chromium in the protective film on stainless steel. This passivation treatment also makes it easier to remove rust if it were to occur.

The stainless steel we commonly use in our stainless casters is 304. After cold work (the process of stamping, forming, surface polishing, etc) a stainless caster usually becomes magnetic in the worked areas. These areas are relatively prone to rust in a corrosive environment. If it is necessary, annealing is the most effective way to restore the non-magnetic properties and enhance corrosion resistance. Actually, it changes martensite back to austenite. In this process, the stainless product is heated to 1800F – 2100F and cooled down slowly. If the temperature is not high enough the corrosion resistance of the stainless will be reduced. This process increases costs a lot. The passivation process washes away free particles and forms a passive coating on the stainless surface. This process is what we do for only stainless caster model G15. It is a relatively economic way to enhance corrosion resistance, but it is not meant to completely restore the non-magnetic properties.

The magnet test is NOT the correct way to verify stainless steel. Stainless steel is graded by the ingredients and percentages. Stainless is a man-made alloy. The nickel content determines the grade of stainless. The chromium content must be 18% or more to be 304 stainless. It starts out as non-magnetic. After a 500-ton press squeezes the nickel it changes the distribution of the nickel. The same is true when the die cuts the stainless increasing the possibility that rust will eventually occur there. All stainless steel is magnetic except austenitic stainless steel which is actually 300 series stainless such as 304 and 316. However, 300 series stainless is non-magnetic only after it is freshly formed. 304 is almost for sure to become magnetic after cold work such as pressing, blasting, cutting, etc. Initially, the cold work causes the stainless to pick up foreign particles such as free iron. Then at some spots, the metallic crystal structure changes from austenite to martensite. 400 series stainless (ie. martensitic stainless steel) is magnetic. Stainless steel containing more nickel (310 and 316 grades) is more likely to remain non-magnetic after cold work.

All stainless steel is NOT necessarily non-magnetic. It is common for stainless to pick up iron ions from the die and tool used during the stamping process. Iron ions cause magnetism and later may cause minor rust. The casters you received are stainless steel even though your magnet may stick to them. We use 304 stainless to make our stainless casters. We do not use 316 stainless because it would ruin our tooling. Our customers use our stainless casters and it is very rare that there is a problem with rust unless their application is extremely caustic. If your application is extremely caustic you should require stainless steel that has gone through both the passivation and annealing processes. Passivation enhances the rust resistance of the stainless surface. The passivation process is not meant to completely restore non-magnetic properties. It is only a relatively economic way to enhance corrosion resistance. It is available on special order for very large volumes at substantial extra cost on some of our stainless casters. We use the passivation process standard only on stainless caster model G15. It removes all ions. Annealing is the most effective way to restore non-magnetic properties and enhance corrosion resistance. However, in this process, if the stainless is not heat treated high enough and then cooled down slowly the corrosion resistance of the stainless steel will be reduced. Annealing stainless is almost cost-prohibitive. When both processes are applied, passivation should be done after annealing.