Important Facts That You Should Know About Rigid Casters

Rigid casters are commonly used in industrial settings to move heavy loads and materials around the factory or warehouse floor quickly and easily. But, what makes them so different from their smaller, lighter counterparts? Read on to find out what you should know about rigid caster wheels to determine if they’re the right choice for your business!

The Basics

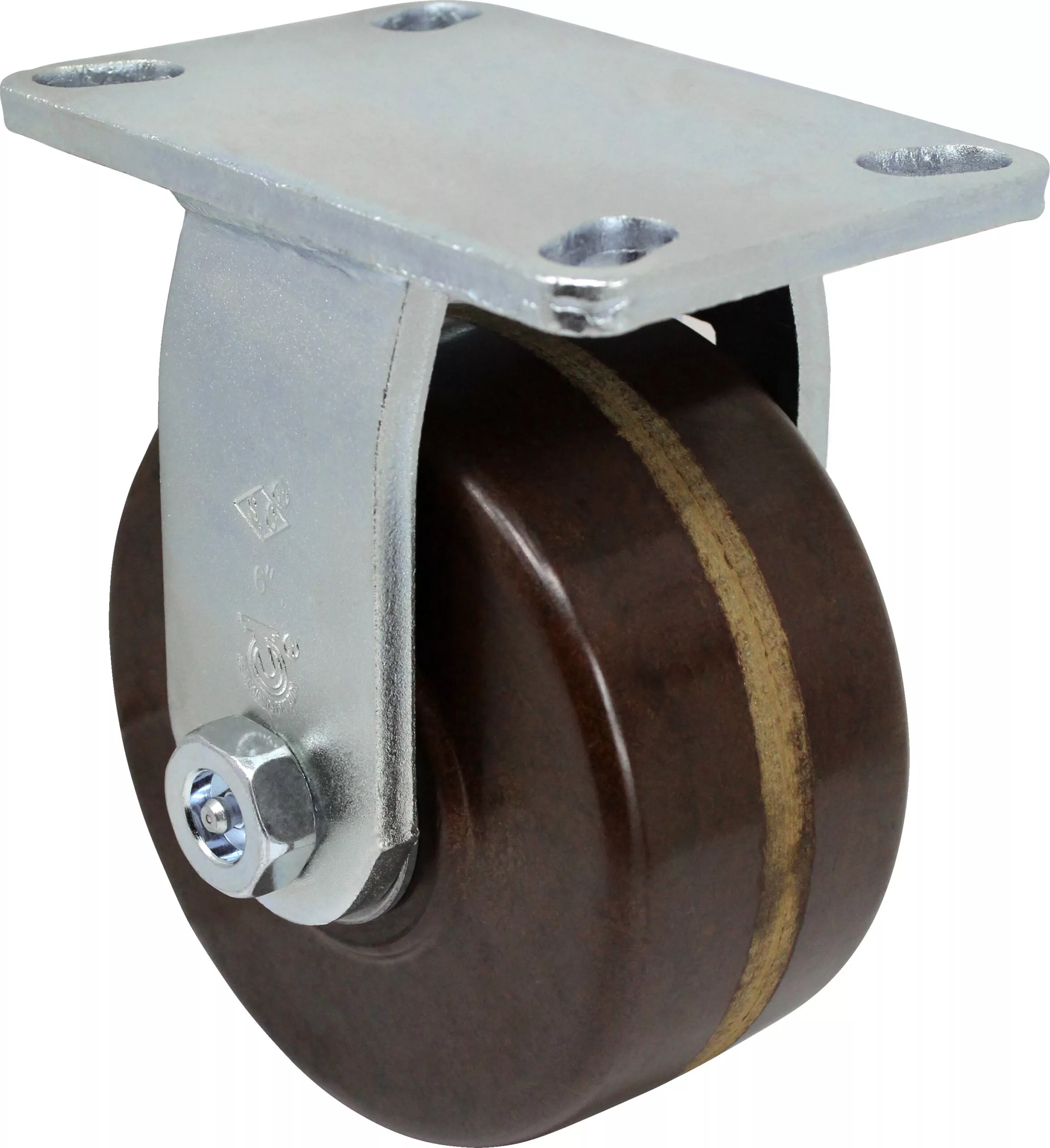

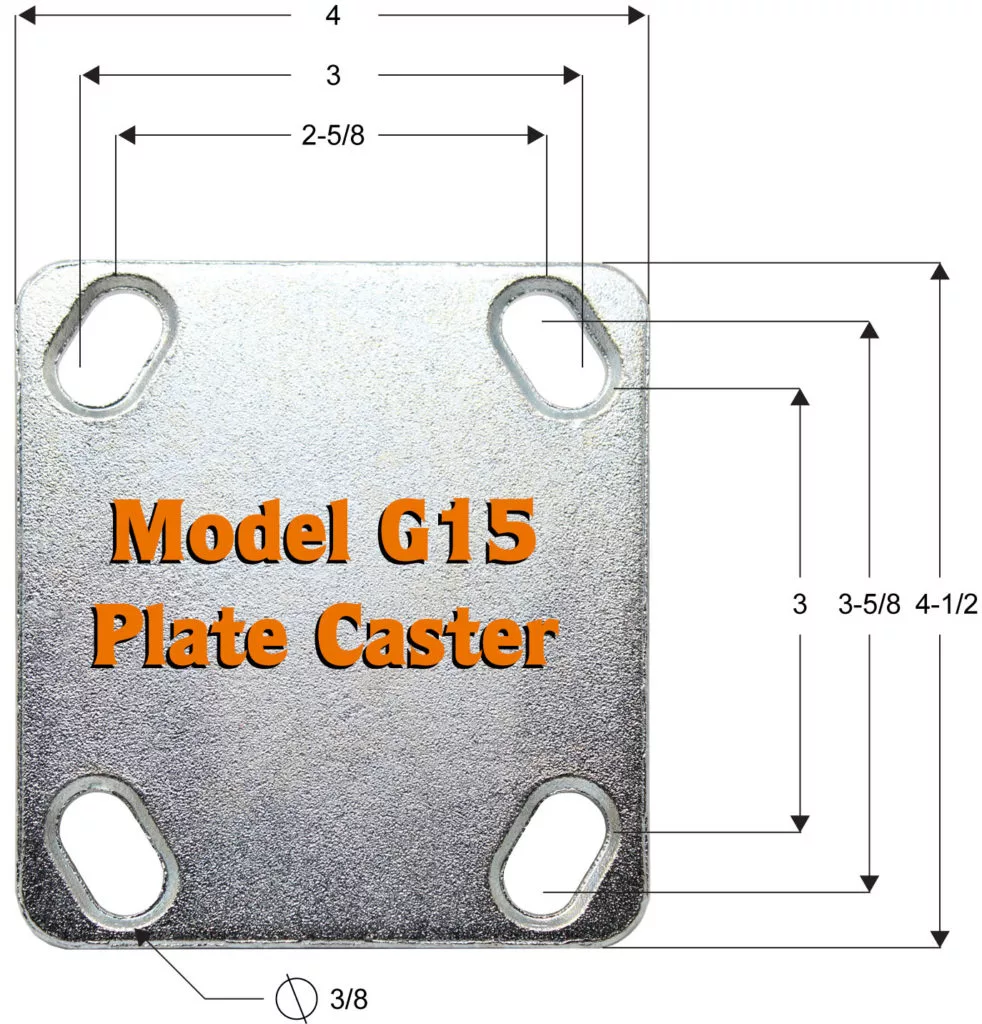

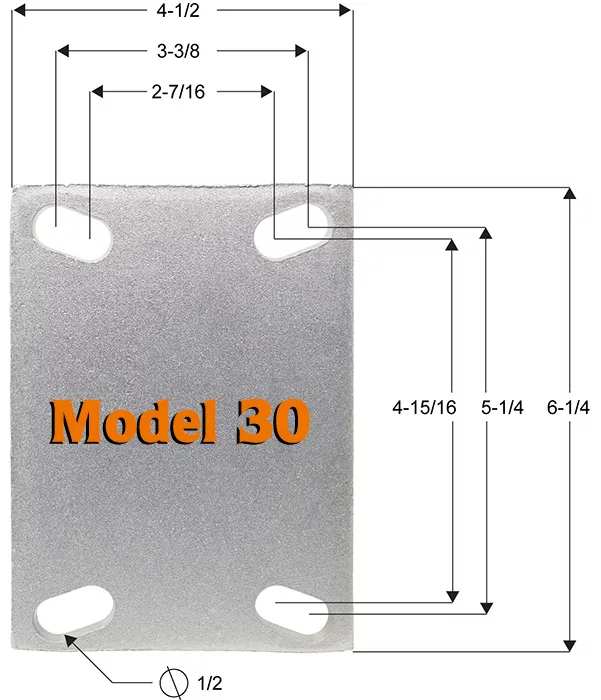

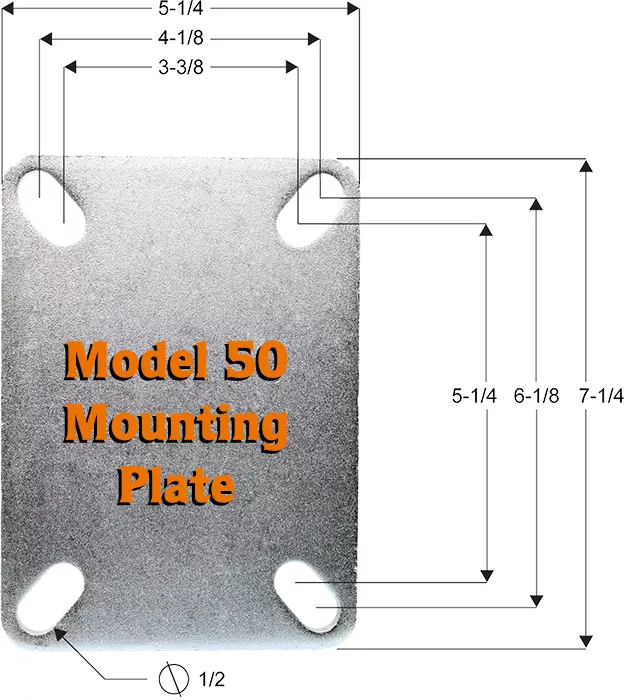

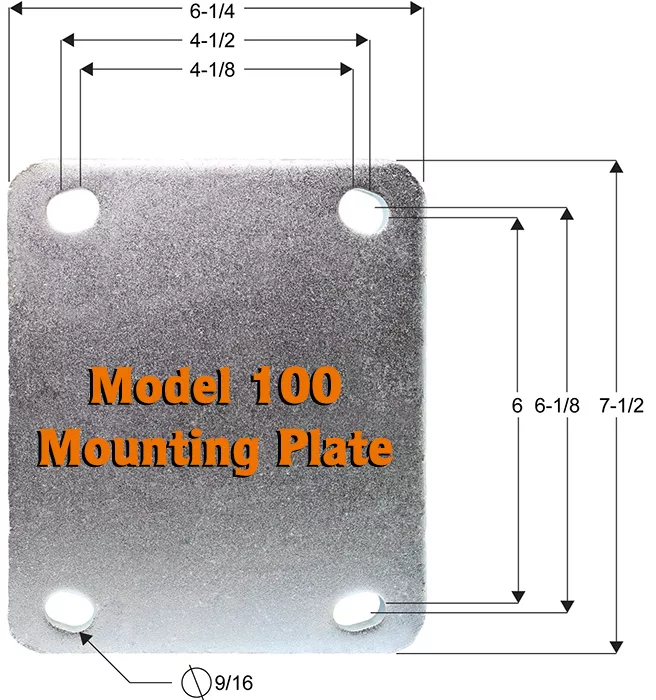

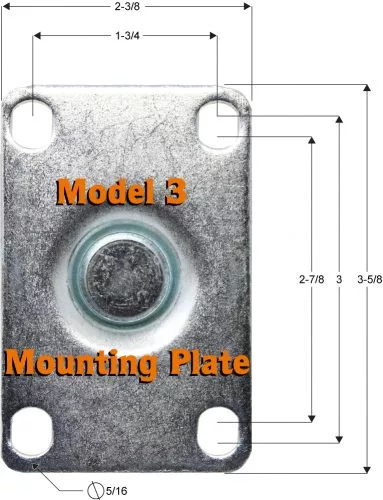

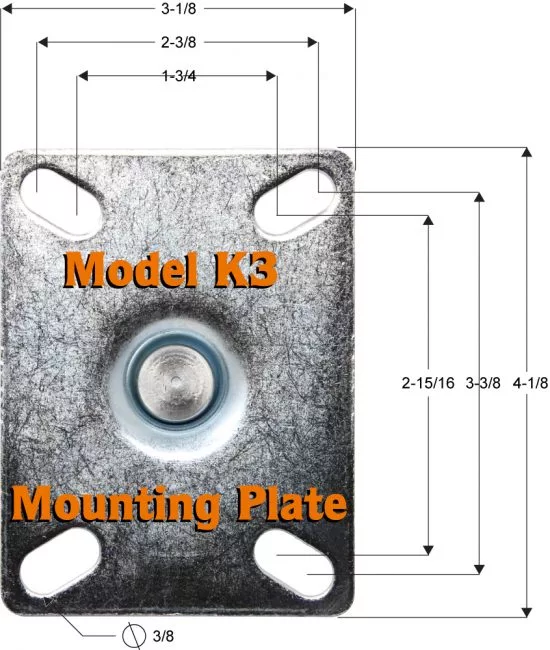

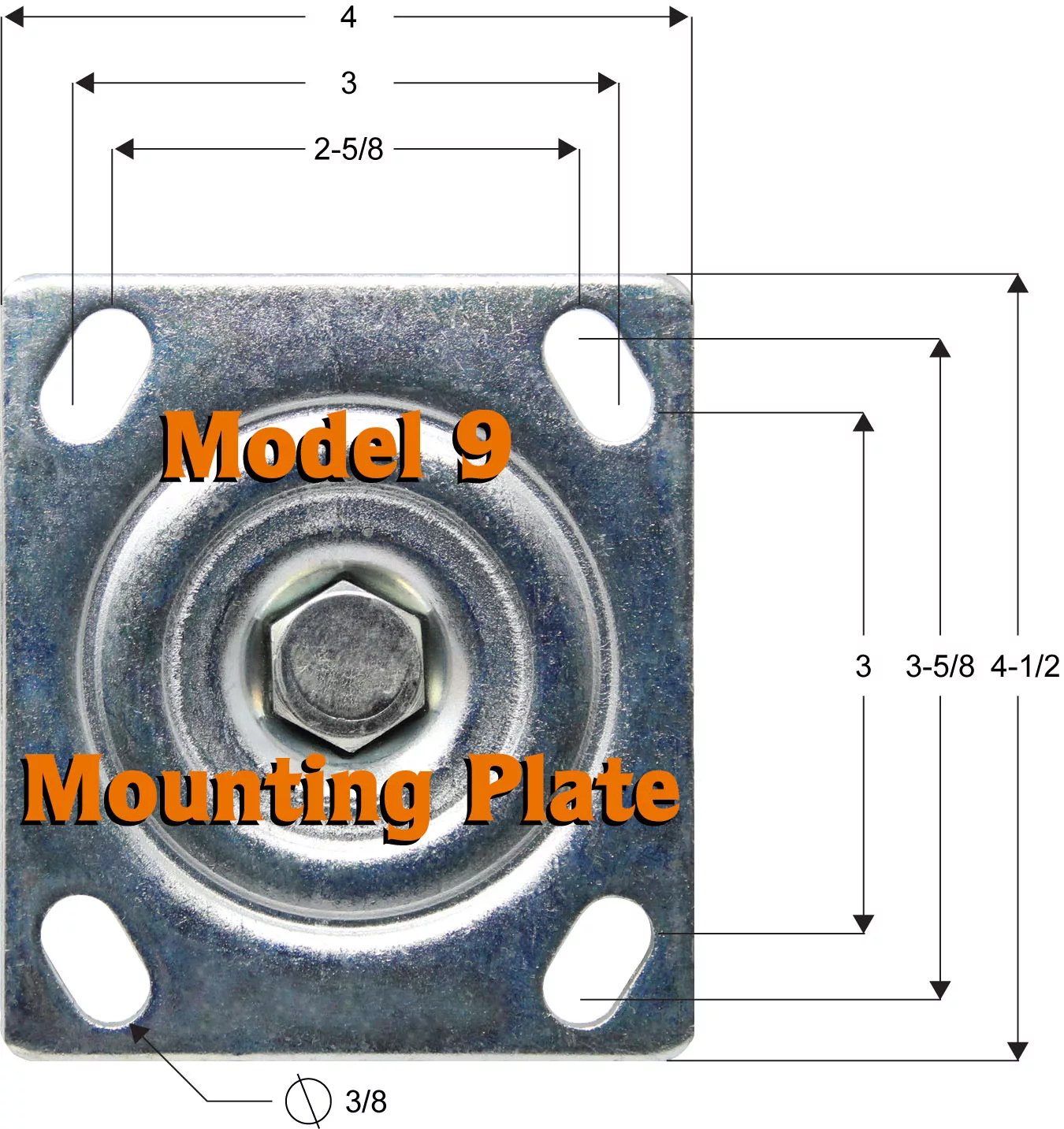

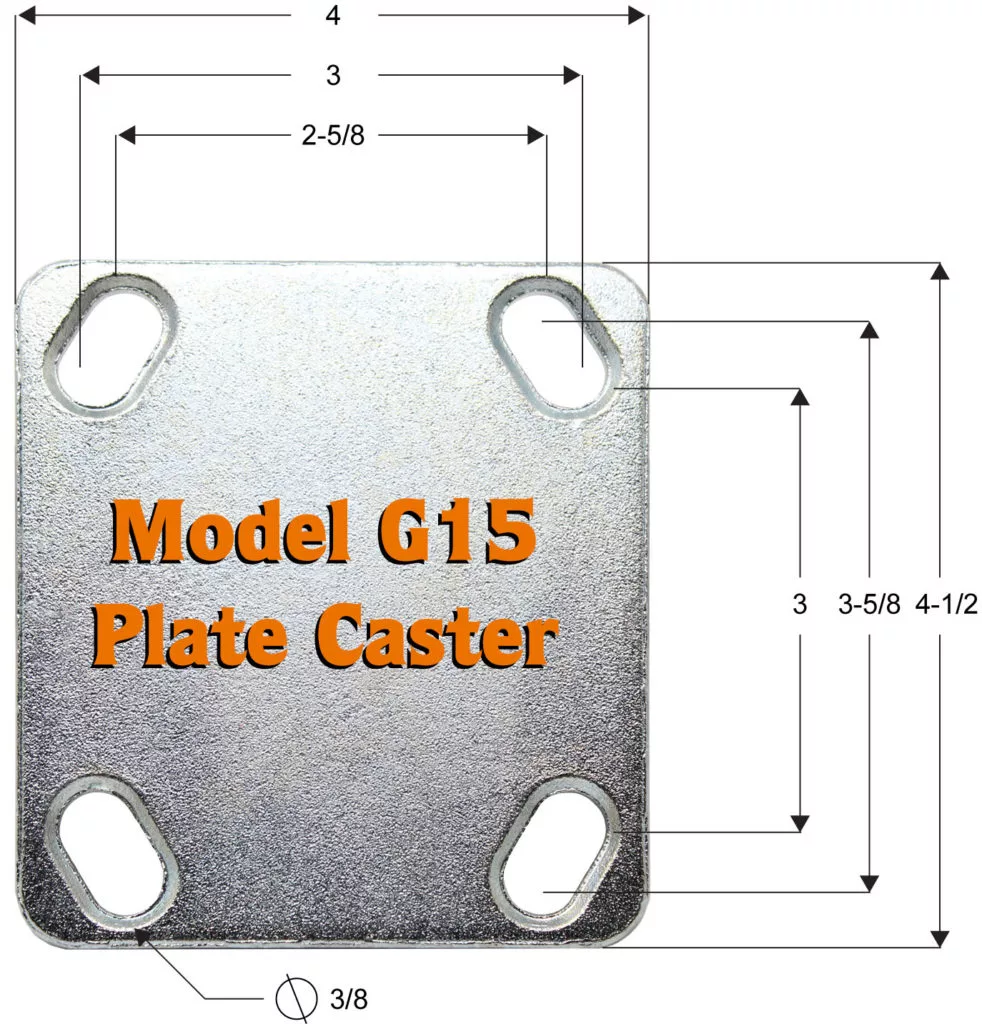

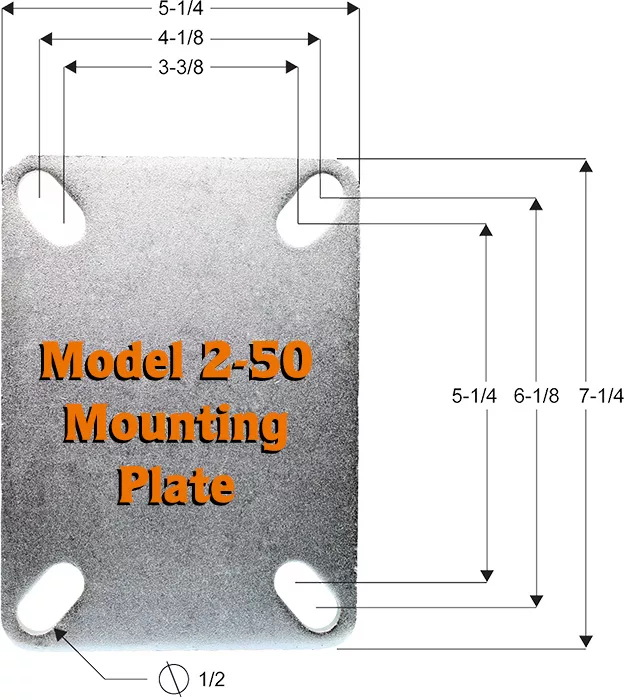

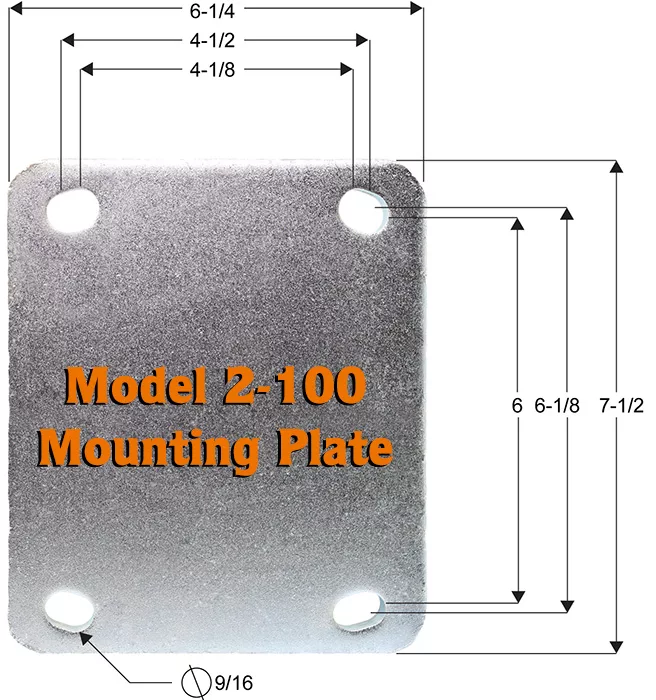

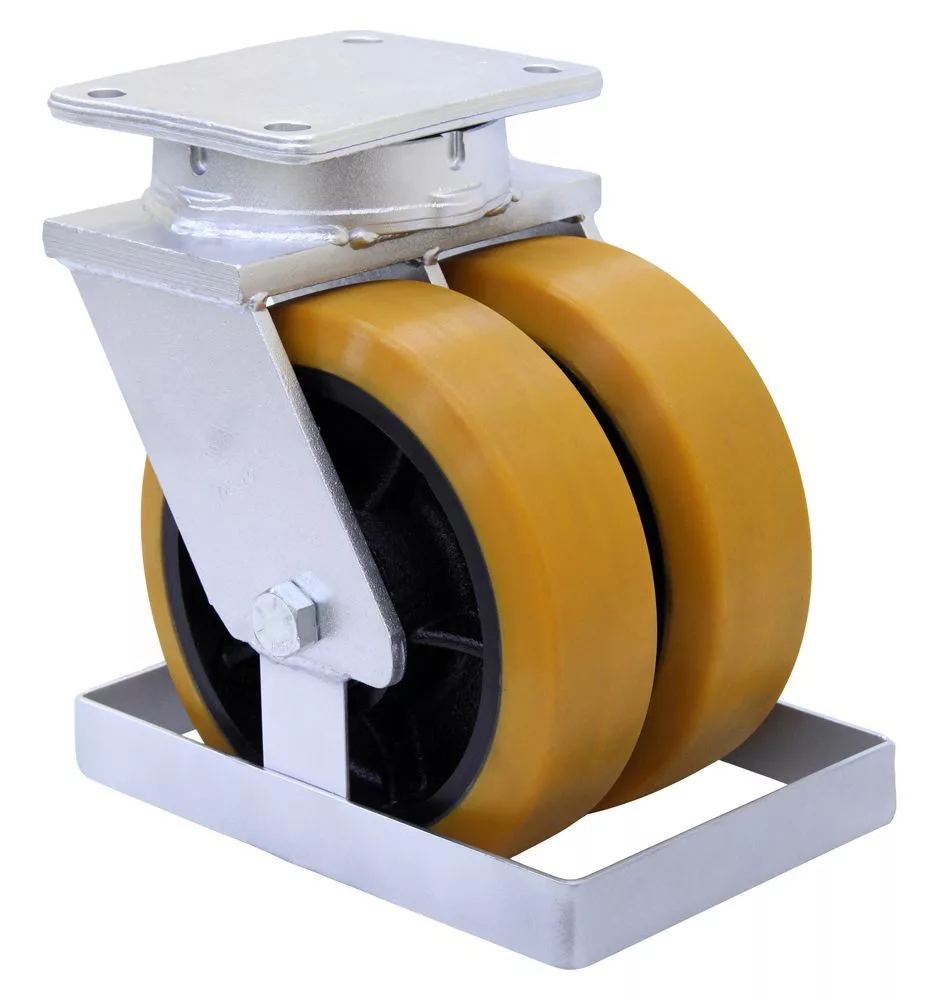

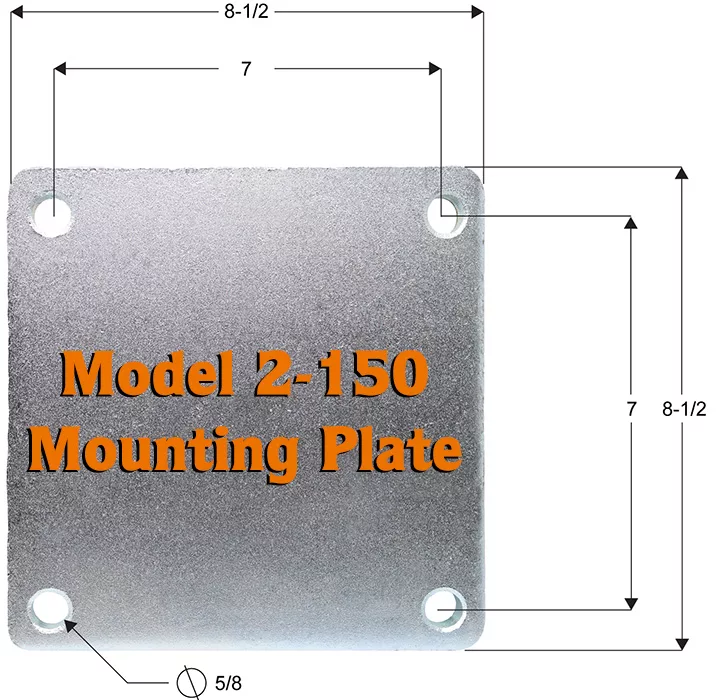

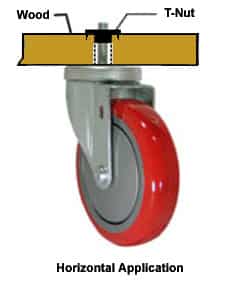

A rigid caster is a type of caster wheel that is attached to a base plate with stems. The wheel is unable to swivel, making it ideal for use in industrial applications where loads need to be transported in a straight line. These types of casters, also referred to as “fixed casters” or “non-swivel casters” are often used on industrial equipment, such as carts, dollies, and hand trucks. While the casters are not designed to be adjustable, you can adjust their position by loosening the stem and rotating the wheel.

Some interesting characteristics and features:

There are several important characteristics to consider when selecting rigid caster wheels for an industrial application. These include load capacity, wheel diameter, tread width, and hub length/bearing type.

- Load Capacity: The load capacity and size of the wheel must be appropriate for the intended application. For example, polyurethane wheels are often chosen for their high load capacity and resistance to wear, while nylon wheels are typically selected for applications requiring low rolling resistance or noise reduction.

- Wheel Diameter: The wheel diameter should be large enough to accommodate the load but not so large that it is difficult to maneuver. Also, the wheel diameter should be proportional to the load capacity of the wheel. For example, a heavy load requires a heavier wheel.

- Tread Width: The tread width should be suitable for the environment and conditions of use. For instance, a narrow tread is more appropriate for low-friction surfaces such as carpeting, while a wide tread is desirable for high-friction surfaces such as concrete floors.

- Hub Length and Bearing Type: Finally, the hub length and bearing type should be considered to ensure that they will work with the caster’s mounting system and provide adequate support.

Where are Rigids used most?

Rigid casters are used in a variety of industries, including automotive, construction, and food service and provide mobility to transport heavy objects that cannot be moved easily by hand. For example, in the automotive industry, rigid casters are used to move cars from one spot to another without damaging the car’s exterior. Construction crews often use rigid casters to move heavy pieces of equipment, such as power tools, lifts and generators and food service workers use rigid casters to move food carts containing hot food from one part of a restaurant to another. Casters are also used on dollies used in warehouses to transport large boxes and other items.

Difference Between Rigid Casters and Swivel Casters

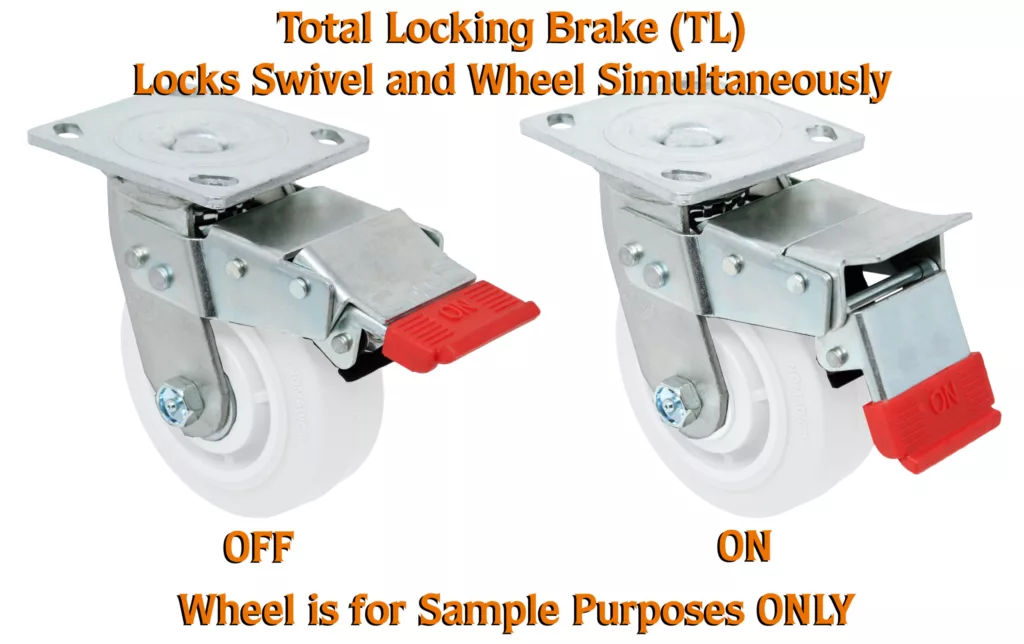

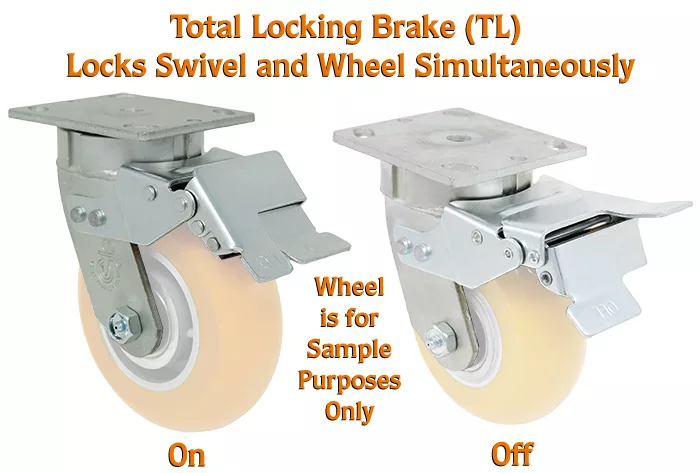

Swivel caster wheels have the ability to rotate 360 degrees, while rigid caster wheels do not. This allows swivel caster wheels to change directions more easily than rigid caster wheels. Swivel caster wheels are also typically smaller in size than rigid caster wheels, which makes them better suited for smaller objects. Rigid casters are typically used on industrial equipment that requires a more durable and stable caster. They are also much sturdier than swivel casters and can handle heavier loads.

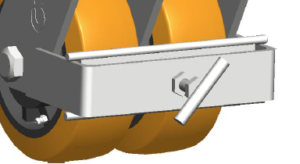

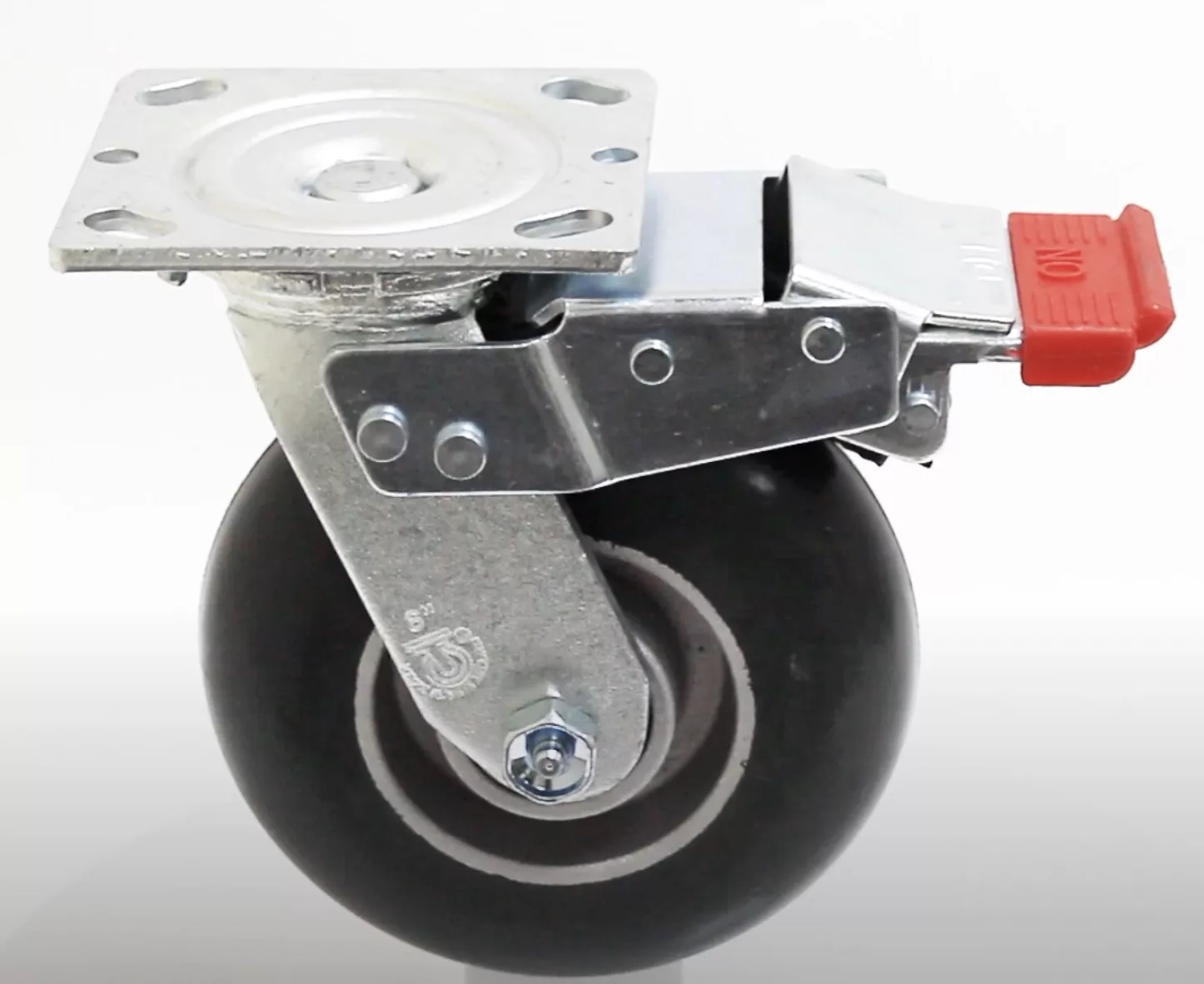

Rigid Caster:

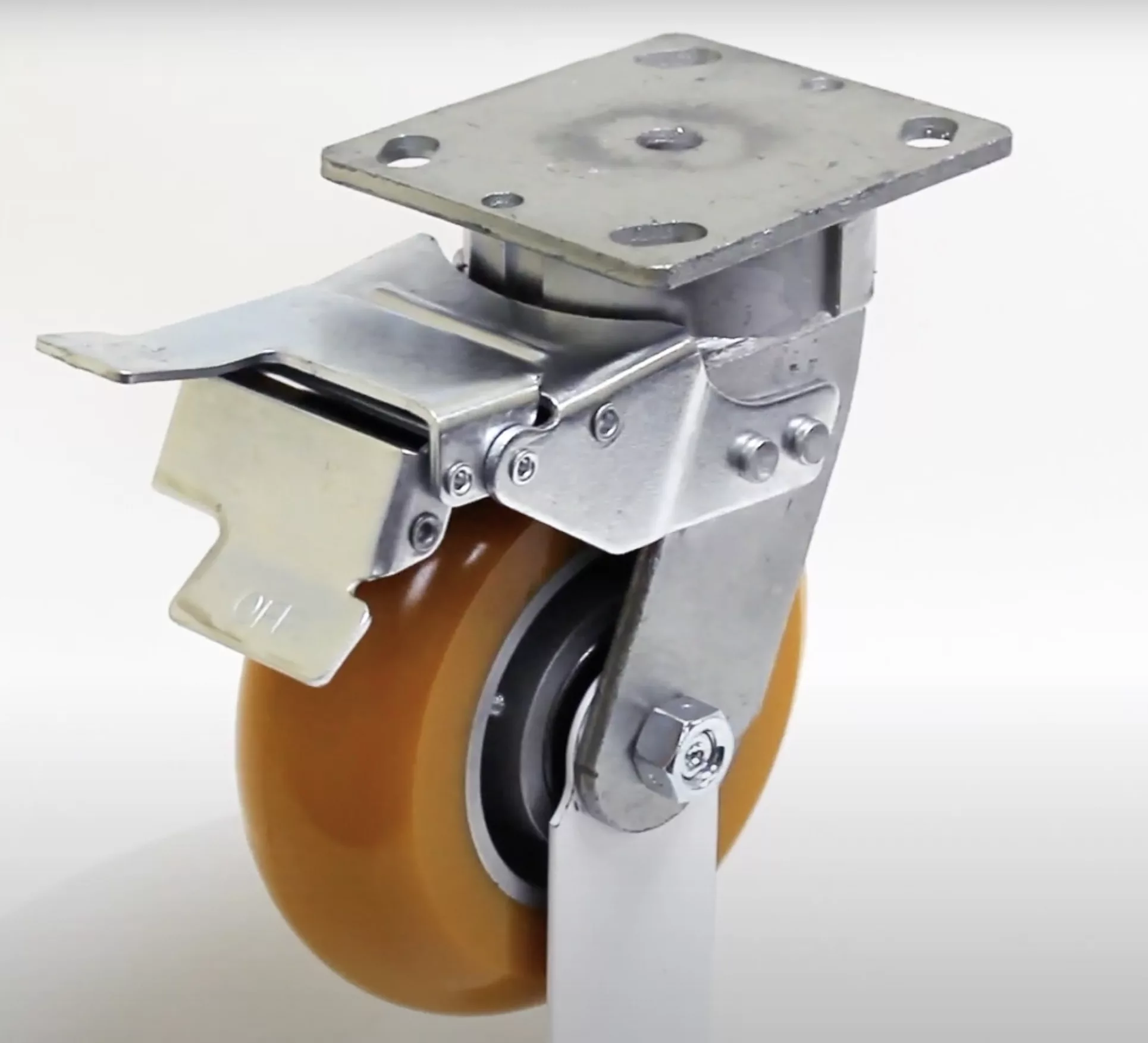

Swivel Caster:

What now?

Rigid caster wheels are an essential part of many industrial and commercial applications. They are strong and durable, and also offer a high degree of stability which is necessary for moving heavy objects. Rigid casters are also easy to install, which makes them a popular choice for industrial equipment. For anyone who needs a reliable wheel solution for their applications, rigid casters should be the first type of caster considered.

Thus, if you’re looking for an efficient and effective way to move heavy loads in an industrial setting, then consider investing in a set of rigid casters. They come in many different sizes, materials, and configurations to suit your specific needs, so be sure to consult with one of our specialists to select the perfect caster wheel for you.