Is Bigger Always Better? Why Caster Wheels Size Matters

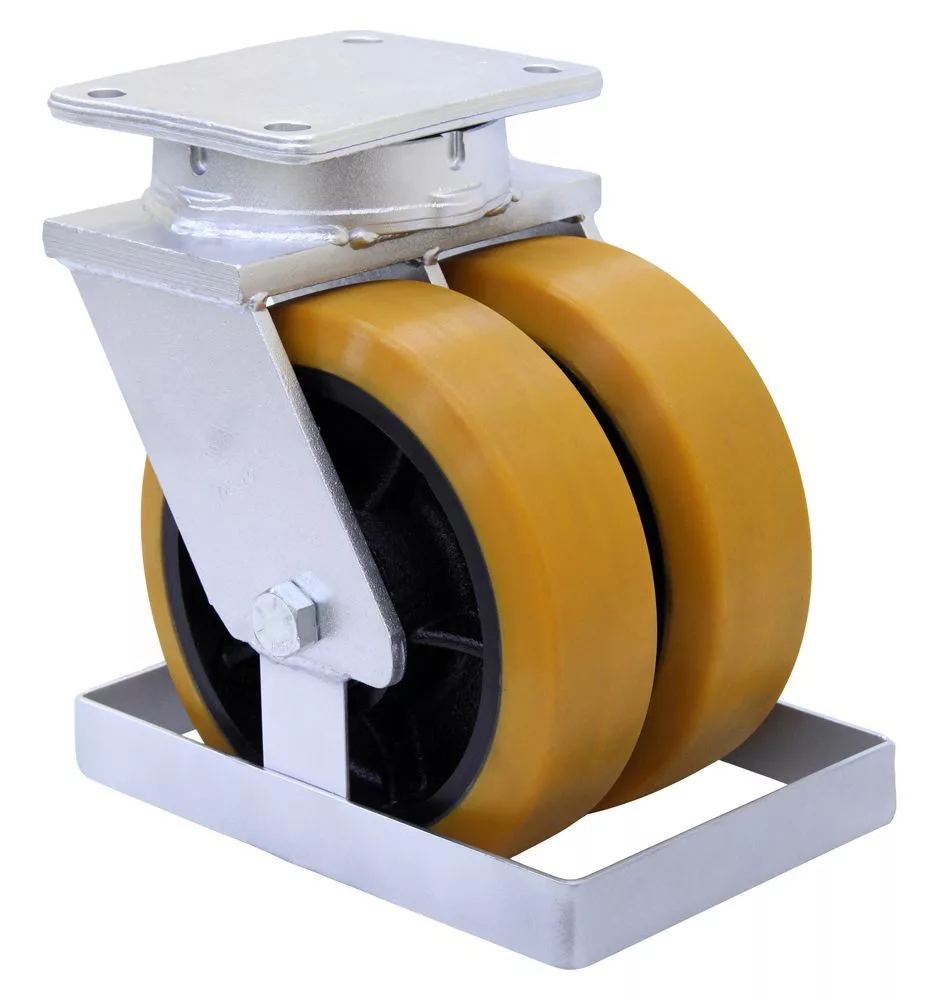

In many industrial and commercial settings, caster wheels are an essential part of moving equipment and materials around. But did you know that the size of your wheels can make a big difference in how well they perform?

If you’re shopping for new caster wheels, or planning to change out your existing ones, it’s important to be aware of the role that caster wheels play in the performance of your equipment. Size determines not only the load-bearing capacity of the wheel but also its ability to maneuver in tight spaces. This article examines why size matters for caster wheels.

Factors to Consider When Choosing the Right Size Caster Wheels for Your Equipment

Choosing the right size wheels for your equipment can be challenging. There are many factors to consider, such as the weight of your equipment, your equipment dimensions, and the type of terrain it will be used on.

The Weight of Your Equipment

The weight of your equipment is one of the most important factors to consider when choosing the right size wheels for your equipment. All wheels are rated by their load capacity, so you’ll want to make sure that the caster wheels you select can safely support the weight of your equipment. For example, if you have a piece of equipment that weighs 100 pounds, you’ll want to choose caster wheels with a load capacity of at least 100 pounds.

Your Equipment Dimensions

When choosing wheel size, it’s also important to consider the width of the item being transported. The width of the item will dictate how big the wheels need to be in order to safely and effectively move the item. For instance, a piece of equipment that is very wide would require larger wheels than a piece of furniture that is narrow.

The Type of Terrain Your Equipment Will be Used On

The type of terrain your equipment will be used on is another important factor to consider when choosing the size of your caster wheels. If you’ll be using your equipment on rough terrain, you’ll want to choose wheels with a high load capacity and large diameter. On the other hand, if you’ll be using your equipment on smooth surfaces, you can choose caster wheels with a lower load capacity and smaller diameter.

Performance Benefits of Choosing the Correct Wheel Size

The size of the wheel is also critical factor to its performance. In almost every industry, size matters. When it comes to caster wheels, this is especially true. There are a few reasons why size is so important for caster wheels. Most people believe that when it comes to wheels, bigger is always better. But is this always the case?

There are three primary advantages of larger caster wheels. First, the larger the wheel, the easier it is to roll over rough or uneven surfaces. Second, bigger wheels can carry more weight without breaking or becoming damaged. Finally, larger caster wheels are less likely to get caught on small objects or debris, making them ideal for use in outdoor or industrial settings.

However, larger wheels also have drawbacks. Larger wheels are more difficult to maneuver, especially in tight spaces. They also take up more space than smaller wheels and may require larger wheel wells or special machinery to keep them from touching the walls. Finally, all other things being equal, larger wheels are more expensive than smaller ones.

The Benefits of Using the Right Size Wheels for Your Equipment

Using the right size caster wheels has many benefits, including improved mobility, increased longevity of your equipment, and improved safety.

Improved Mobility

The right size caster wheels will improve the mobility of your equipment. This is because the wrong size wheels can cause your equipment to be unstable and difficult to move. For example, if you have a piece of equipment that is too heavy for the caster wheels you are using, the wheels may break or become damaged. This will make it difficult to move your equipment and could even lead to an accident.

Increased Longevity of Your Equipment

Another benefit of using the right size caster wheels for your equipment is that it will increase the longevity of your equipment. This is because using the wrong size caster wheels can wear down or damage your equipment over time. For example, if you use a small wheel on a large piece of equipment, the weight of the equipment may cause the wheel to break or become damaged. This will then require you to replace the wheel, which can be costly.

Improved Safety

Finally, using the right size caster wheels for your equipment can also improve safety. This is because using the wrong size caster wheels can make your equipment more likely to tip over or cause an accident. For example, if you use a small caster wheel on a large piece of equipment, the weight of the Equipment may cause it to tip over when you turn a corner or stop abruptly. This could lead to serious injury or even death.

Conclusion

Casters come in a variety of sizes and each size has its own advantages and disadvantages. The size of the wheel helps determine how much weight the equipment can support, how well the equipment moves, and how much wear and tear the equipment will experience.

Important tradeoffs often need to be made when choosing the size of your caster wheels. Overall, while smaller wheels may be more maneuverable, they can also create more vibration and noise. Conversely, even though larger wheels can handle more weight and provide a smoother ride, they may not fit into smaller spaces.

Given the difficulty of choosing the best wheel size for your application and the importance of making the best decision for your organization, please feel free to contact our expert team with your questions. We’re always here to help!