How To Properly Maintain Your Caster Wheels

Ever marveled at how effortlessly your office chair glides across the room or how easily you can move your shopping cart through the supermarket aisles?

Whether they’re attached to your office chair, heavy-duty machinery, or even your shopping cart, casters play a vital role in enabling seamless movement.

Over the years, we’ve worked hand-in-hand with diverse businesses – retail stores, hospitals, factories, warehouses, you name it! Each industry has its own unique needs and taught us valuable lessons about the significance of caster wheel maintenance.

However, just like any other component, casters require regular maintenance to ensure they continue to function smoothly. This article delves into the art of maintaining your caster wheels, troubleshooting common issues like caster flutter, and understanding when it’s time for a replacement.

Maintaining your casters is as important as caring for the main body of your equipment. Small as they might be, well-maintained casters keep your operations rolling smoothly!

This article provides a comprehensive guide on properly maintaining your caster wheels, troubleshooting common issues, identifying when it’s time for replacement, and selecting the appropriate replacements.

The Importance of Regular Caster Maintenance

Drawing from decades of hands-on experience in the industry, we’ve observed first-hand how regular caster maintenance can be a game-changer for business operations.

It’s not just about smooth movement, it’s about enhancing the overall productivity and efficiency of your business.

Here are a few reasons why caster wheel maintenance should top your priority list:

- Improved performance: Regular maintenance ensures smoother movement and load-carrying efficiency.

- Longer lifespan: Maintenance slows down wear and tear, extending the caster’s lifespan.

- Increased safety: Regular checks help identify and fix potential safety hazards.

- Cost-effectiveness: Catching minor issues early on saves you from costly repair jobs down the line.

Additionally, regular caster maintenance also contributes to the eco-friendly initiatives of your business. By extending the lifespan of your casters, you reduce waste and promote sustainability and that is something we can all get behind.

Related: Caster Safety and Solutions: How to Ensure Stability and Avoid Risks

Caster Wheels Maintenance: A Step-by-Step Guide

Ready to get your hands a little dirty?

Don’t worry, maintaining your caster wheels is not as daunting as it may seem. Here’s your handy step-by-step guide:

Step 1: Regular Check-ups

Inspect your caster wheels regularly for signs of damage.

During the inspection, look for:

- Signs of wear or damage on the wheel and the caster’s body.

- Accumulated debris that might obstruct the wheel’s movement.

- Any loose or missing parts.

Perform a visual inspection every month or after heavy-duty usage. Note down issues for future attention. Replace parts or casters which show significant damage. And finally, clear any debris or obstructions and tighten any loose parts.

Step 2: Clean and Lubricate

Clean the caster wheels every so often. You will need a soft cloth, a suitable lubricant (e.g., WD-40, silicone spray), and a brush or toothpick.

During cleaning:

- Wipe off any dirt from the caster’s surface with the cloth.

- Apply lubricant to all moving parts of the caster.

- Use the brush or toothpick to work the lubricant into hard-to-reach areas.

- Wipe away excess lubricant with a clean cloth.

Remember to wear protective gloves to protect your skin from potential irritants in the cleaning products.

Step 3: Swivels Check

A smoothly operating swivel ensures easier maneuverability.

During the cleaning process:

- Remove the caster using a suitable tool (e.g., socket or wrench).

- Use a small brush, toothpick or cotton swab dipped in rubbing alcohol to clean the swivel.

- Let the swivel air dry before reinstalling the caster.

Step 4: Caster Tension Adjustment

If pushing your equipment feels like a gym workout, you might need to adjust the caster’s tension.

For adjustment of the caster:

- Loosen or tighten the screws that hold the caster in place until you achieve the desired movement of ease.

Step 5: Inspect Hardware Fasteners

Fasteners hold the caster together and ensure its proper functioning.

During the inspection:

- Check for any damage such as bends, cracks, or breaks.

- Ensure all parts are securely tightened.

- Look for signs of corrosion or rust.

If it is damaged then replace the damaged fasteners immediately to prevent the caster from falling apart.

FAQs: Frequently Asked Questions About Caster Wheels

Even with regular maintenance, problems with caster wheels are more common than you think.

We often get similar queries from our customers. Here are some answers to frequently asked questions to help you troubleshoot common problems:

Q1: Why are my caster wheels squeaking?

This one is a common issue and it is usually a cry for help from your caster for some love.

Possible Causes: Lack of lubrication, debris in the wheel, worn out wheel.

Solutions:

- Lubricate the caster wheel, focusing on the axle and swivel bearings.

- Clean the wheel to remove any debris.

- If the wheel is worn out, consider replacing it.

Q2: My caster wheel is stuck and won’t rotate, what can I do?

If your wheel is giving you a tough time, it is asking for a little cleaning session.

Possible Causes: Debris caught in the wheel, rusting, lack of lubrication.

Solutions:

- Check the wheel for any debris and clean it.

- If your caster wheel is rusting you may need to replace the wheel or the entire caster.

- Keep your casters well lubricated to ensure smooth operation.

Q3: I have a wobbly caster (Caster Flutter), what could be the reason?

Most likely cause? Some replacements are in order.

Caster flutter, a type of instability most noticeable when turning, can cause the wheel to oscillate, affecting steering and safety. It’s often caused by high loads, speeds, loose swivels, incorrect mounting, bent legs, or improper design. To reduce flutter, ensure proper caster mounting, maintain optimal swivel tension, and choose casters with suitable design features for your specific needs.

Possible Causes: Loose fasteners, worn-out swivel, broken wheel.

You can reduce or minimize caster flutter by:

- Using a longer kingpin.

- Reducing the caster angle by using narrower caster wheel.

- Improving friction by applying a dry lubricant (e.g., talcum powder) to the swivel assembly.

- Using a larger bearing.

- Increasing the distance between the axle and the top of the plate.

Solutions:

- Tighten all the hardware fasteners.

- If the swivel or wheel is worn out, replace them.

Q4: I’m finding it hard to maneuver my equipment, could my casters be at fault?

If moving your equipment feels like an uphill task, the casters are asking for help.

Possible Causes: Over-tightened casters, a caster type unsuitable for your flooring, or a damaged swivel.

Solutions:

- Adjust the tension of the caster.

- Choose the correct type of caster wheel for your flooring to ensure smoother movement.

- If the swivel is damaged, replace it.

Remember, if you run into a problem that you can’t solve, don’t sweat it! Our team at Caster City is always ready to roll to your rescue. Just give us a shout!

Recognizing the Signs: When is it Time to Replace Your Casters

No matter how diligently you maintain your casters, they, like all things, have a lifecycle. It’s essential to recognize the signs that indicate it’s time to retire your old casters and bring in new ones.

Here are a few key signs:

- The Wheel is Visibly Worn or Damaged: Excessive wear or visible damage to the caster wheel such as cracks, chips, or flats, are clear signs that it’s time to replace your wheel.

- Caster is fluttering: A common problem characterized by wobbling and instability, often occurs in both light and heavy-duty casters, affecting everything from shopping carts to industrial machinery. It is caused by changes in caster angle during movement, leading to oscillation

- Persistent Noise or Squeaking: If your caster wheel continues to make a noise even after cleaning and lubrication, it’s hinting at some internal damage. Time to bring in a new wheel.

- Frequent Sticking or Jamming: If your caster wheel has a mind of its own and refuses to move smoothly despite your best efforts, it might be time to swap it for a new one.

- Visible Rust or Corrosion: If your caster, especially the swivel or wheel, shows signs of rust or corrosion that can’t be removed, it is recommended to replace it to avoid any potential accidents caused by sudden breakage.

- Difficulty in Movement: If your equipment suddenly feels like it’s gained a ton, and adjusting the caster’s tension or changing the caster type doesn’t solve the issue, it’s a sign that your caster wheels need a change.

Remember, while maintaining your casters regularly can extend their lifespan, replacement becomes inevitable over time.

Choosing the Right Replacement Casters

Selecting a new set of casters isn’t as simple as buying a new pair of shoes. It’s a bit more complex, and there’s more at stake here. Here are some pointers to consider when looking for a replacement:

-

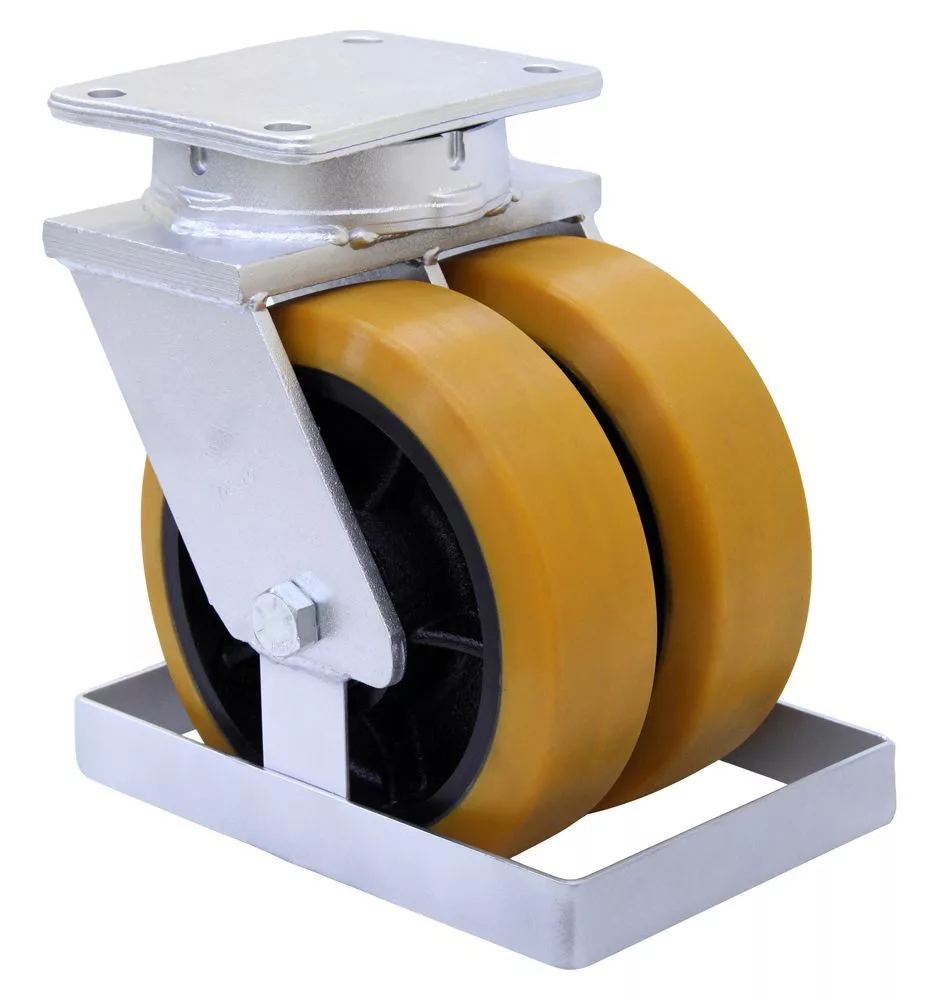

- Load Capacity: Your new caster should be able to handle the load of your equipment. If you’re replacing a caster on an industrial cart, for example, you’ll need a caster with a high load capacity. Our range of industrial casters is designed to handle substantial loads while ensuring smooth operation.

- Application: Think about where and how the equipment is used. If it’s for outdoor use, consider casters that are resistant to weather conditions. If it’s for use in a hospital or an office, consider casters that operate quietly and do not mark floors.

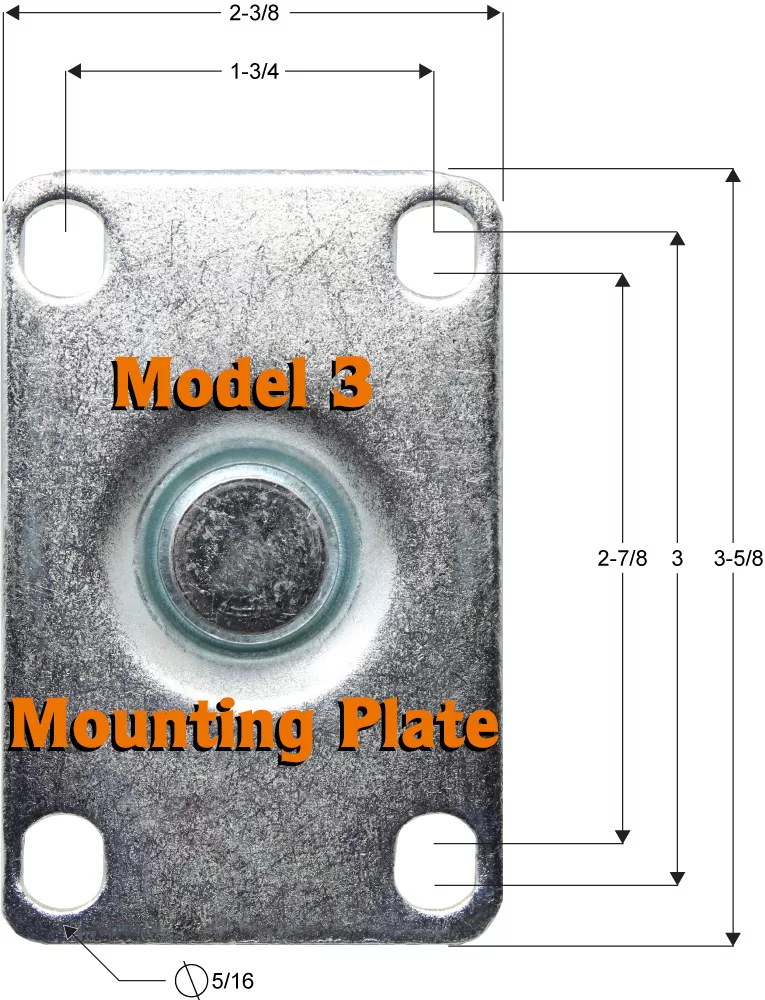

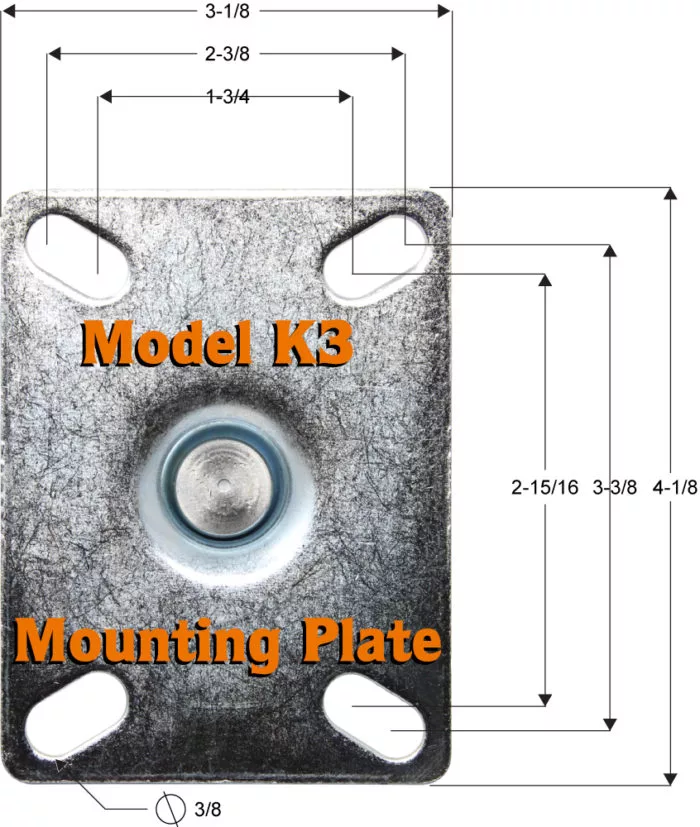

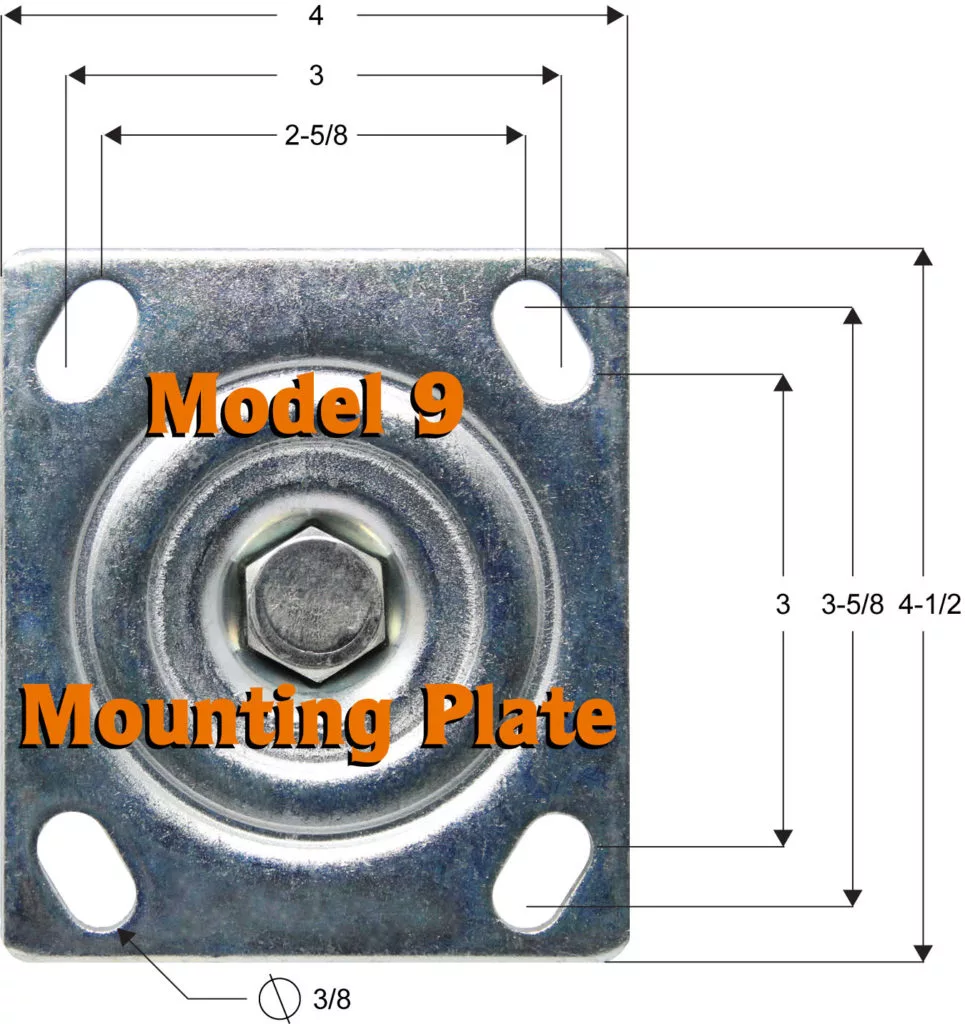

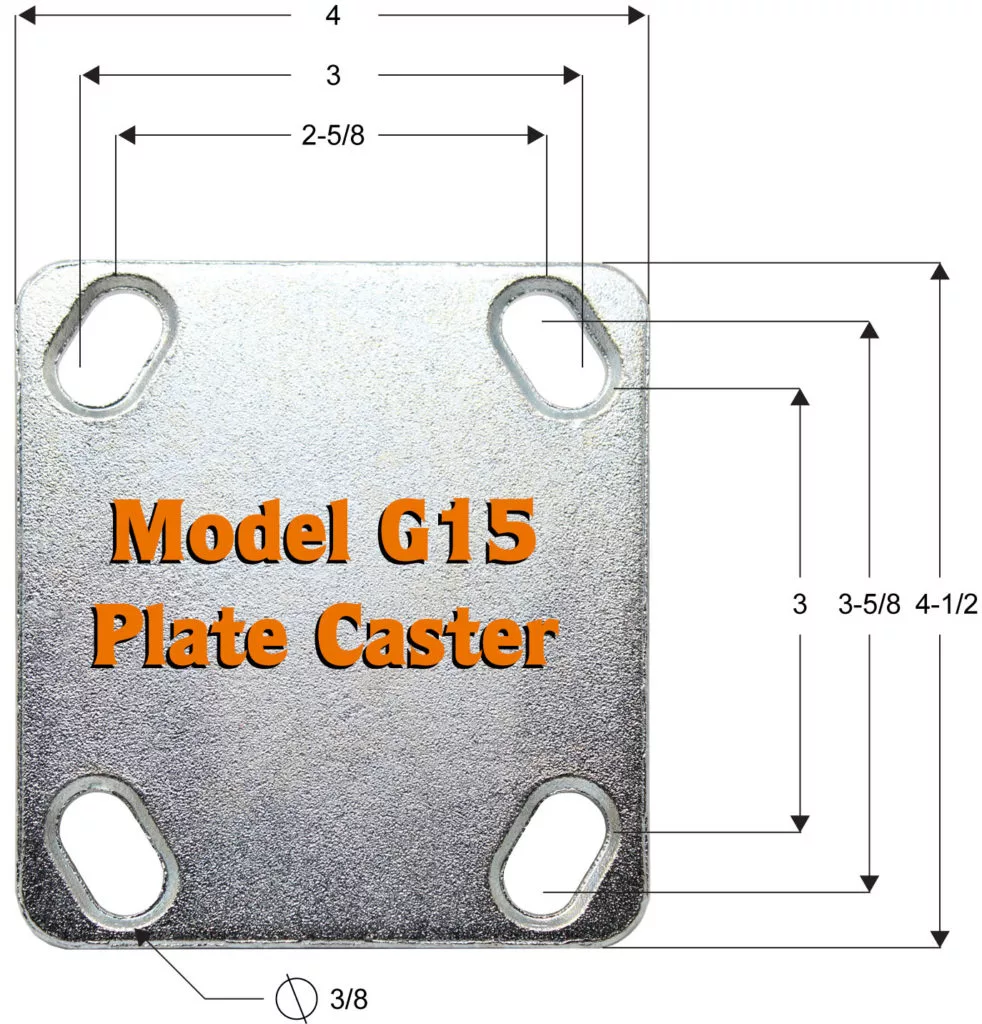

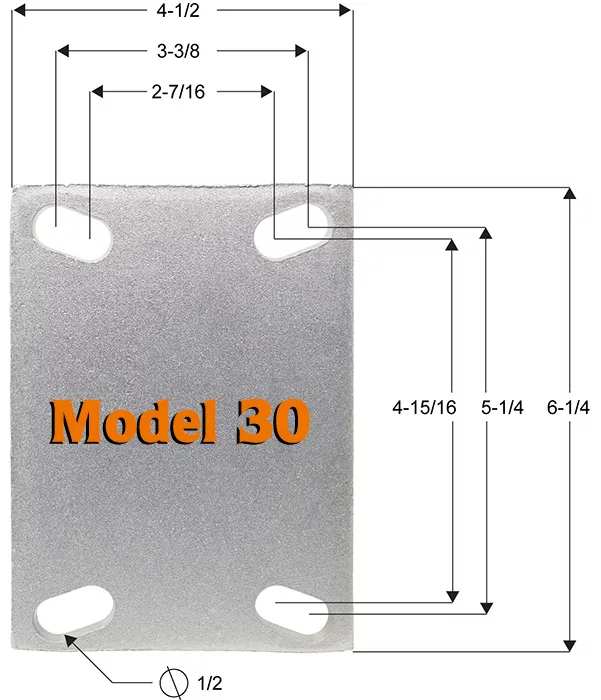

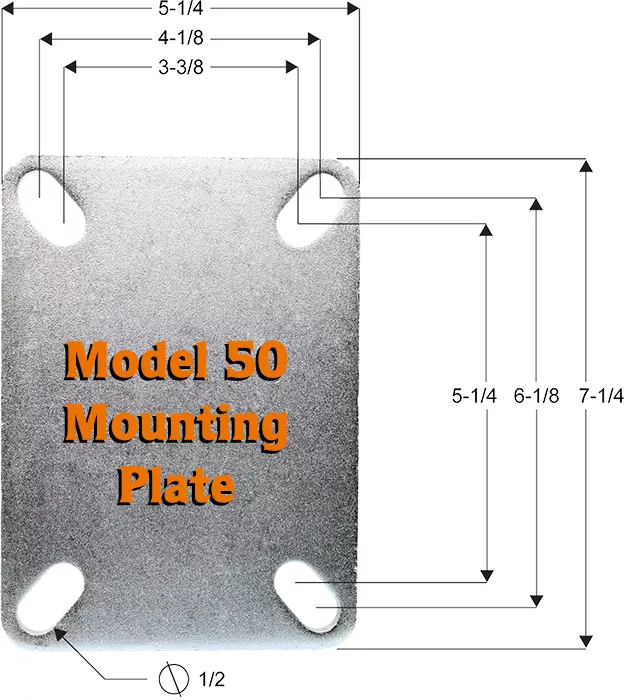

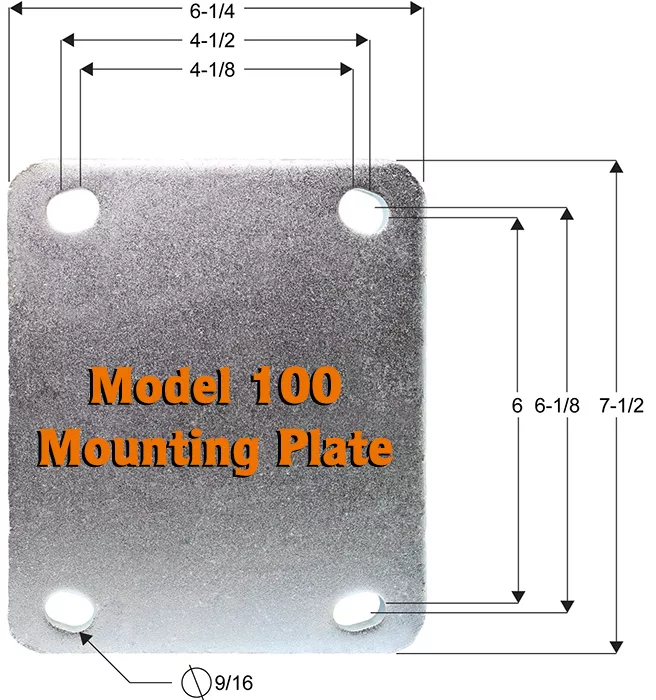

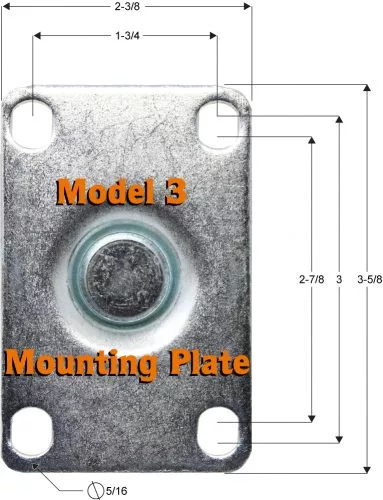

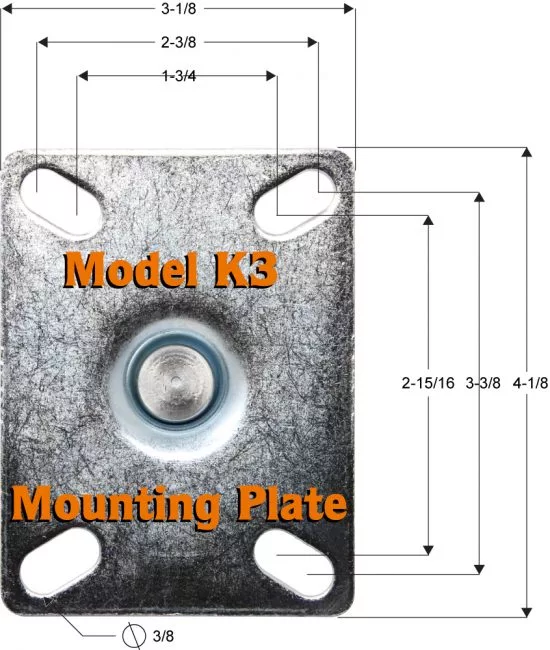

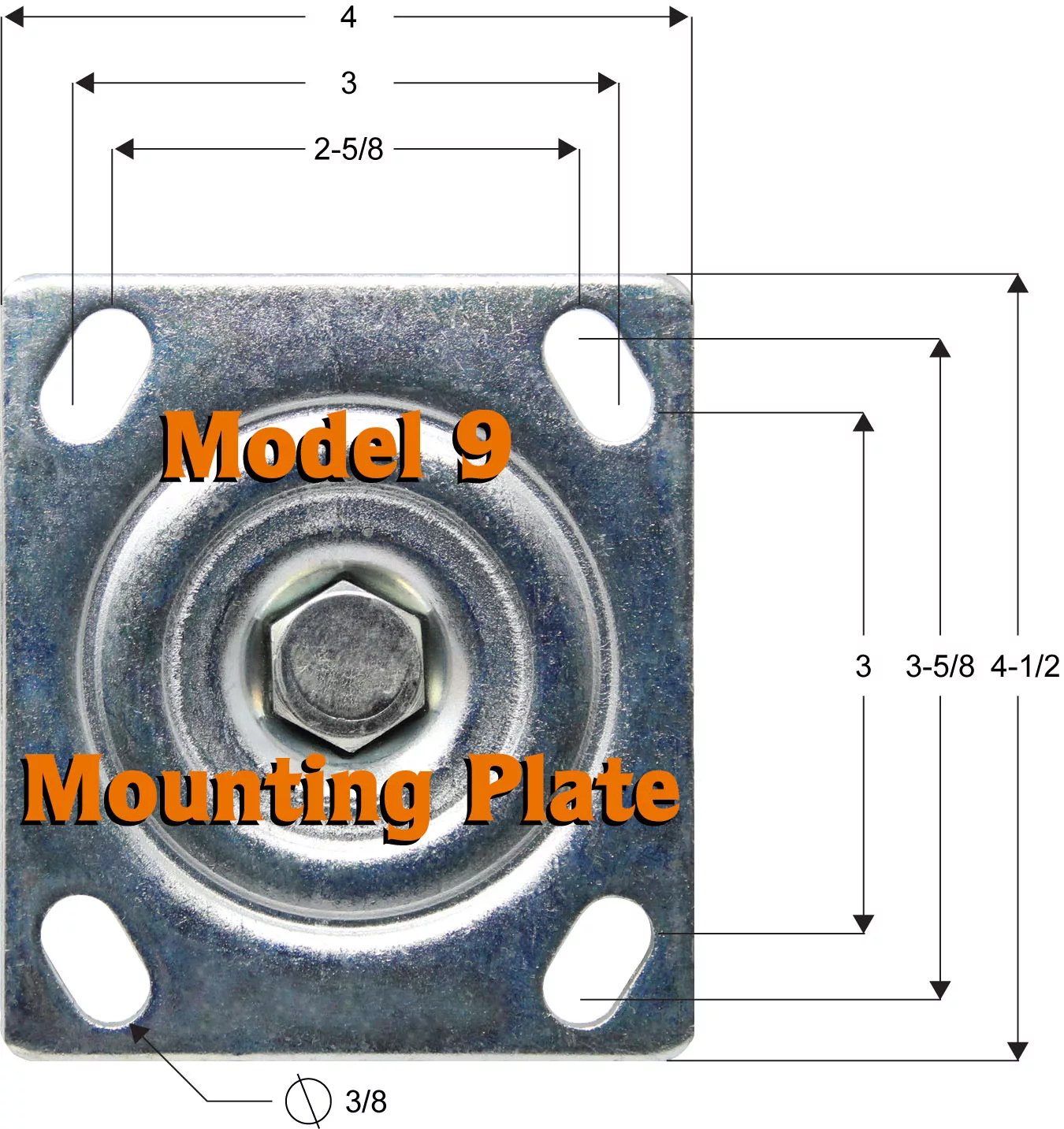

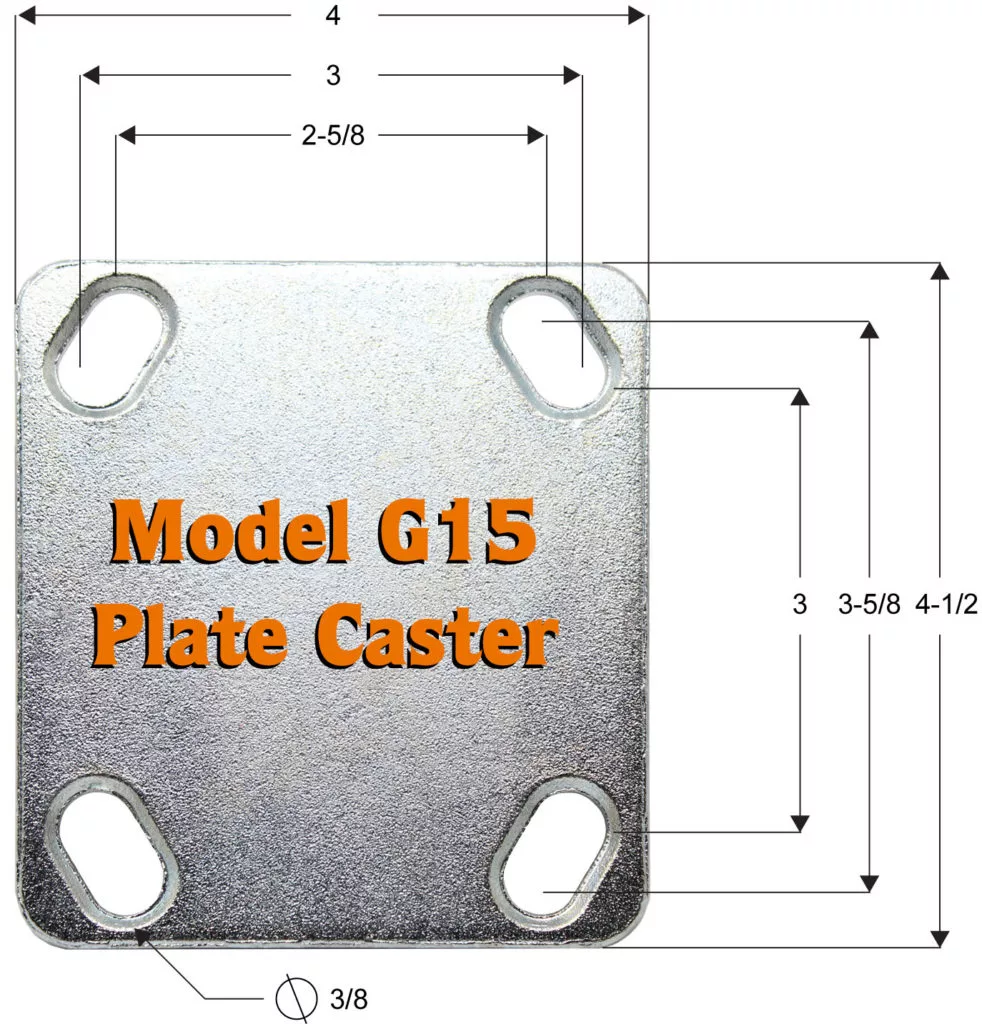

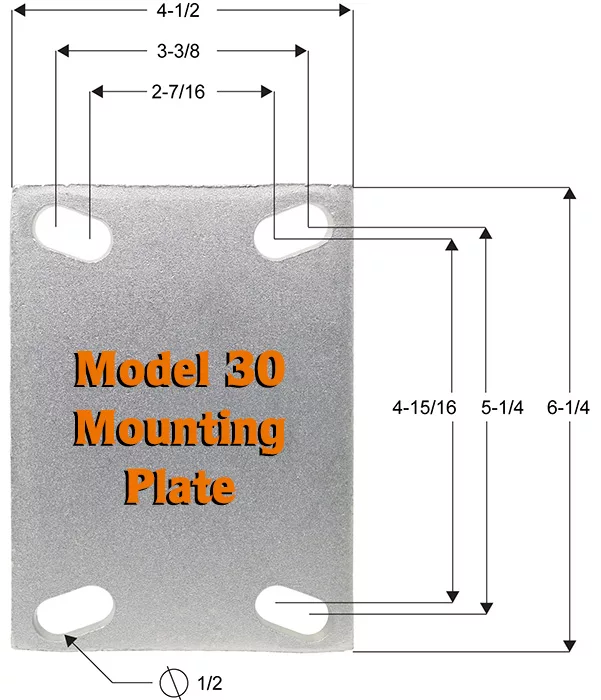

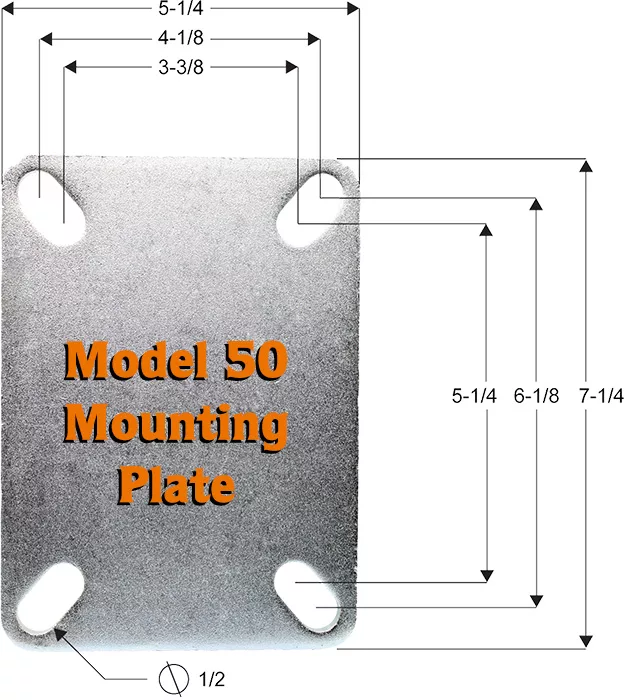

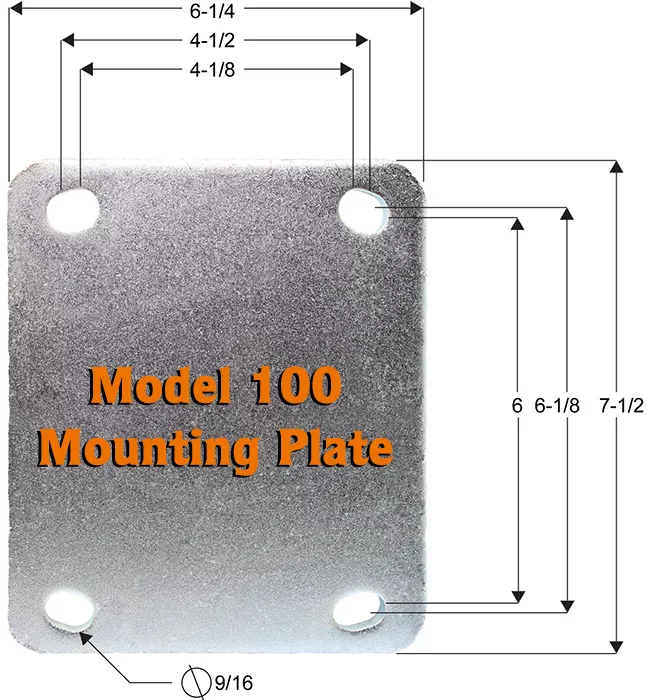

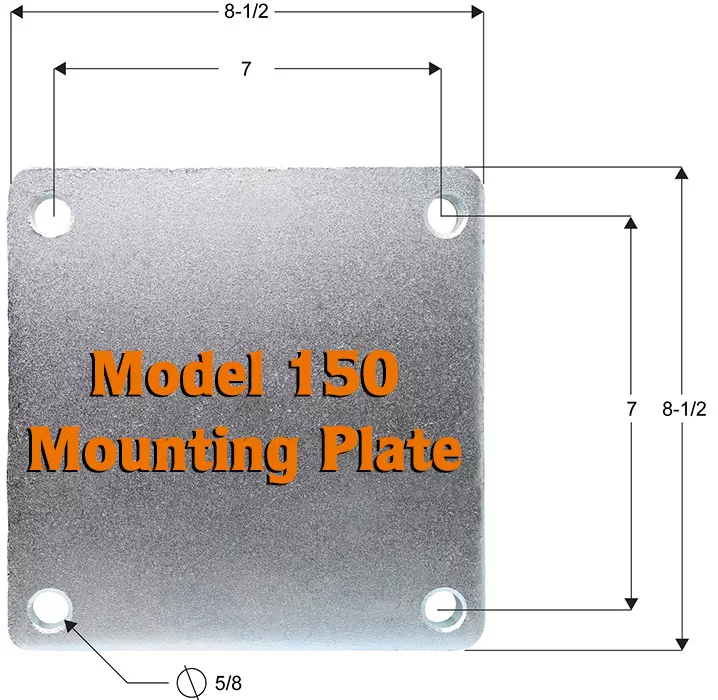

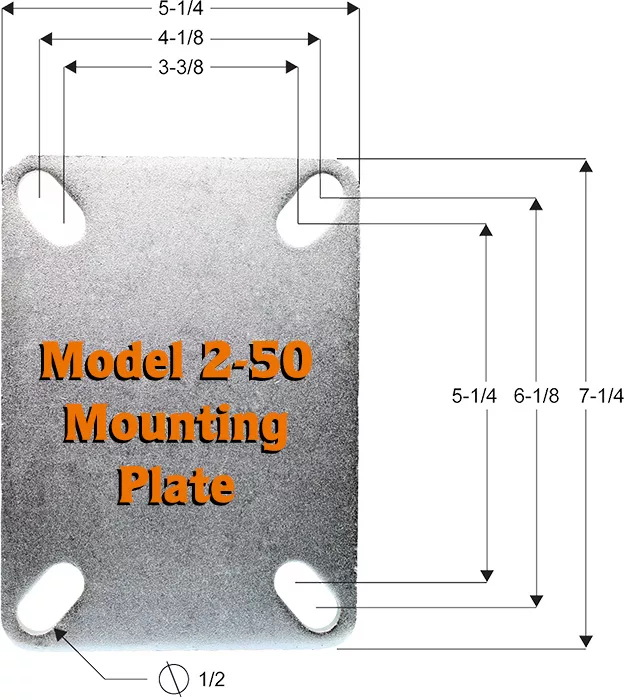

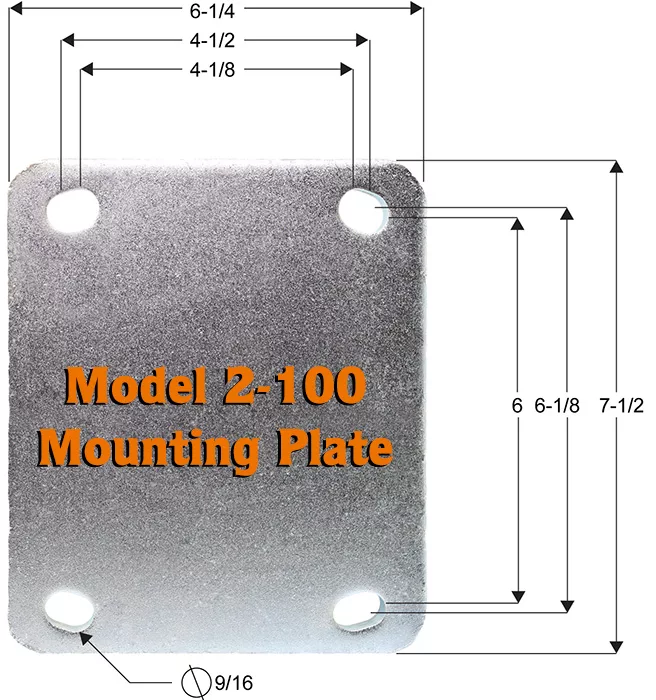

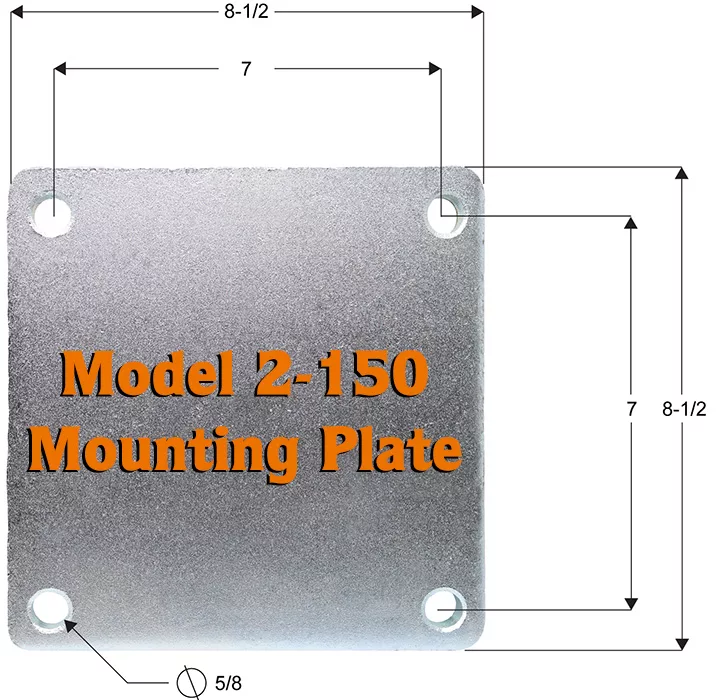

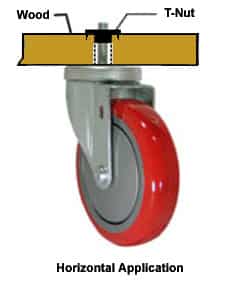

- Mounting Type: Consider the mounting type of your current caster. If it’s a plate caster, you’ll need a replacement that can be bolted onto your equipment. If it’s a stem caster, you’ll need a replacement with a compatible stem size and type.

-

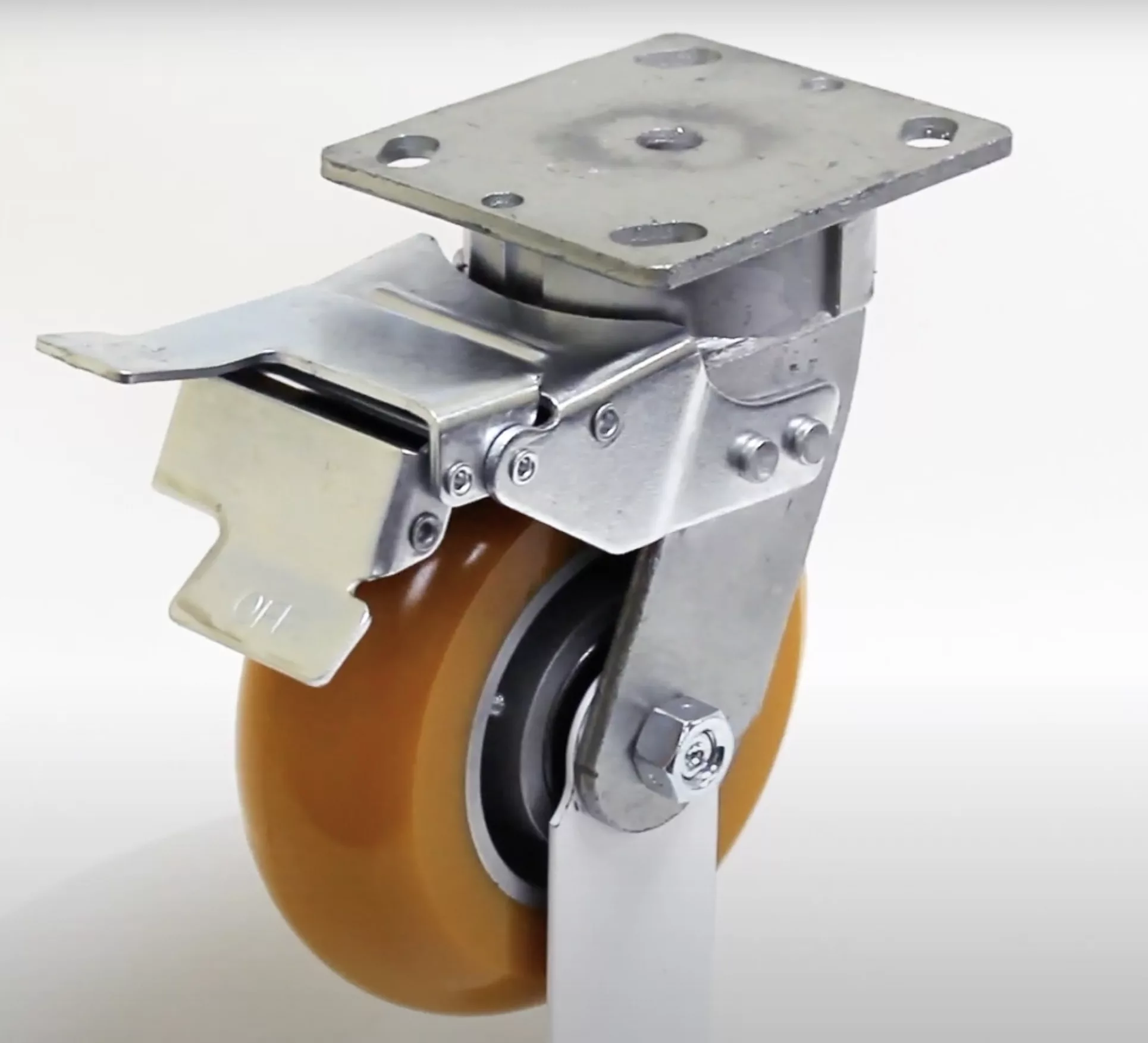

- Wheel Material: The material of the caster wheel plays a crucial role in its durability and performance. Polyurethane wheels are resistant to many substances and work well on various floor types. Rubber wheels, while providing good cushioning, may not be the best for heavy loads.

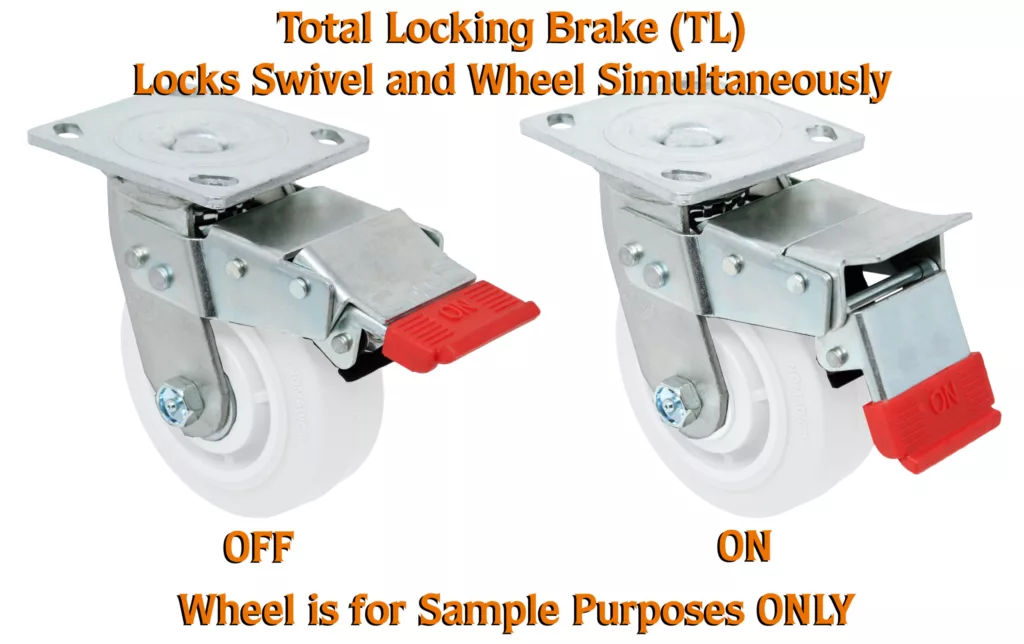

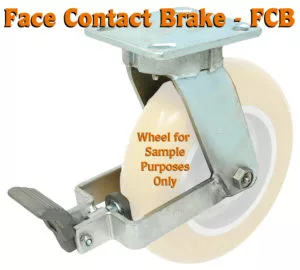

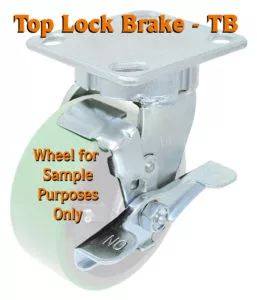

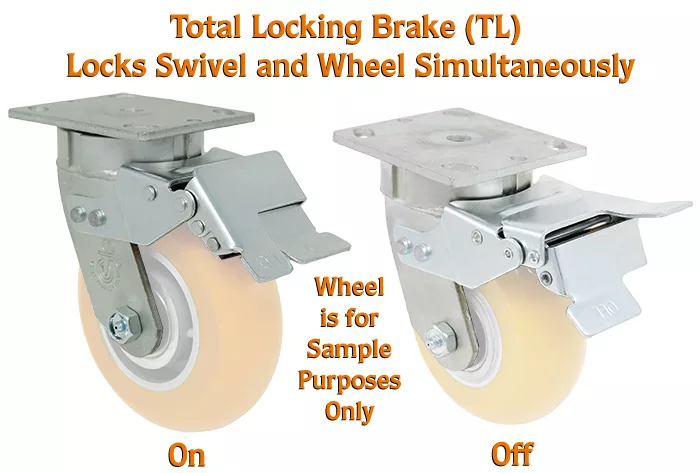

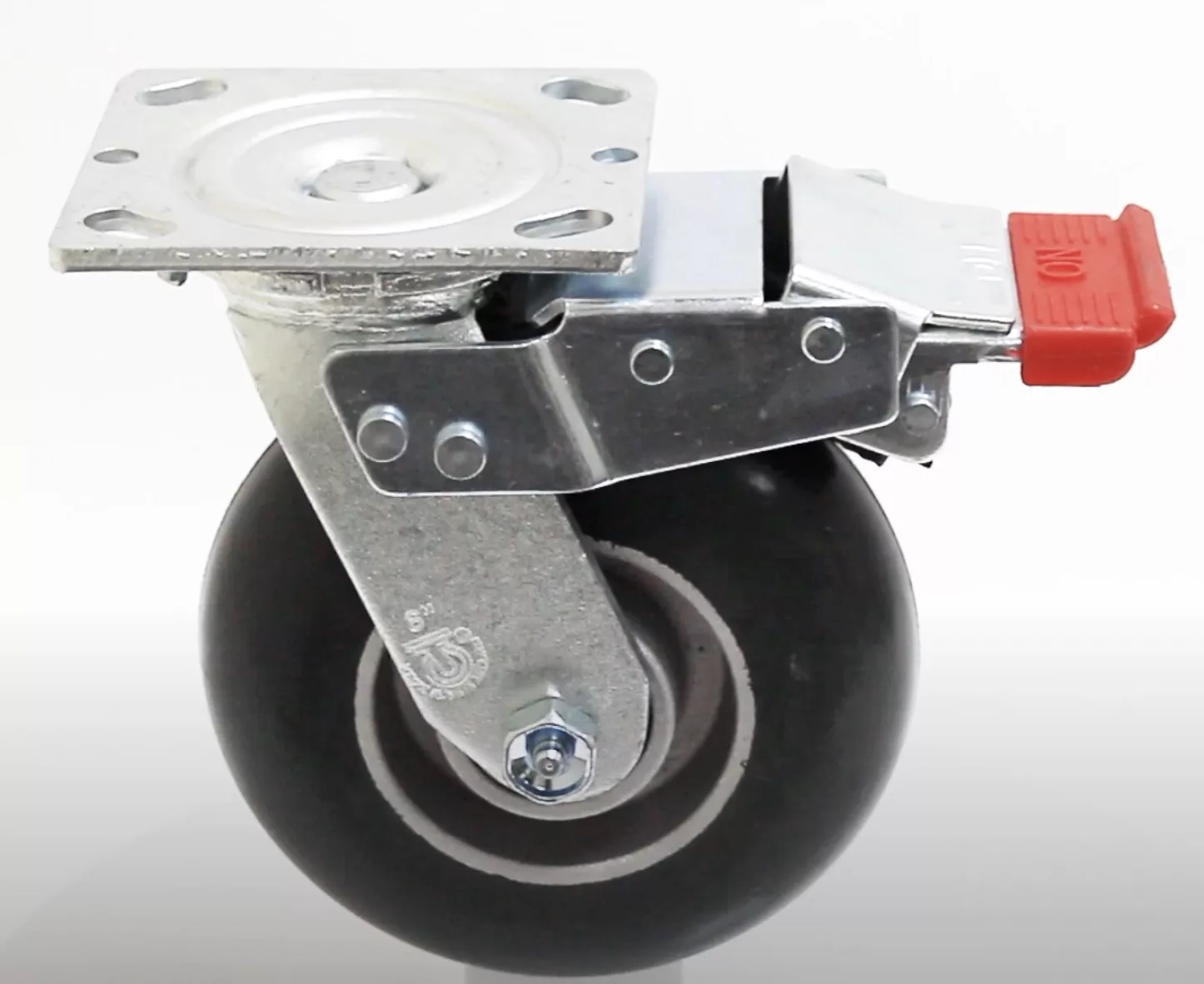

- Locking Mechanism: If your previous caster had a brake or lock mechanism, you might want to ensure your replacement caster has the same feature for consistency and safety.

- Fix Caster Flutter: Mitigate caster flutter by using a longer kingpin, reducing the caster angle, applying a dry lubricant to the swivel assembly, using a larger bearing, or increasing the distance between the axle and the plate top.

Choosing the right replacement can be a bit of a puzzle, but don’t worry, we’ve got your back. If you need help selecting the perfect caster, feel free to reach out to us.

Key Takeaways to Keep Your Business Rolling Smoothly

In the dynamic world of business, no component is too small to be ignored, not even the casters under your equipment! With proper maintenance, routine checks, and timely replacements, your casters can continue to provide reliable service, keeping your operations running smoothly and efficiently.

We hope that you found this comprehensive guide useful and informative. We’ve journeyed through the world of caster maintenance, troubleshooting, and even replacement.

At caster city, we’ve been your trusted partner in the caster industry, providing durable, high-performance caster wheels that meet the diverse needs of various industries. Our long history in the caster industry equips us with the knowledge and skills to provide valuable insights and tailored solutions for your unique caster needs.

Contact us today for more information, advice, or assistance with all your caster needs. Here’s to ensuring a smooth ride ahead!