Tips on Choosing the Right Caster or Caster Wheel

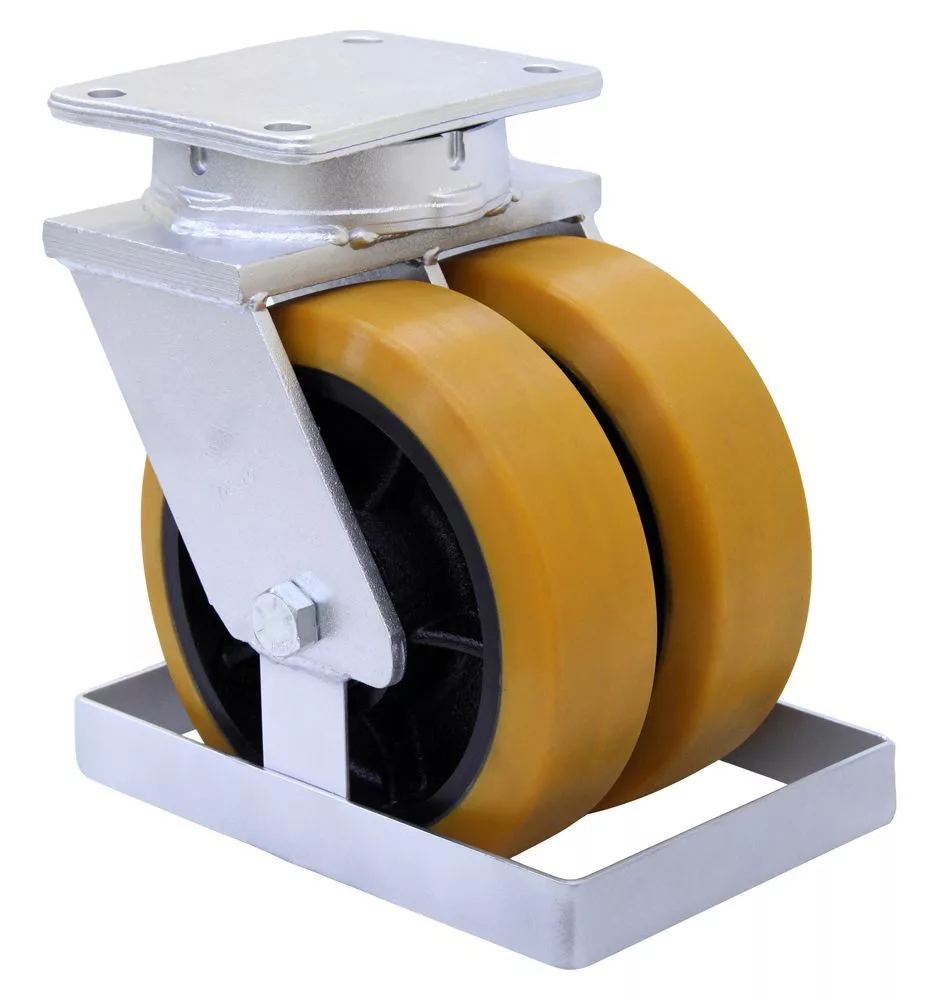

Caster City Blogs2023-09-01T22:00:19-07:00It is our view that you are not purchasing a mere wheel or caster. You are buying a product which must work for you. The internal handling of materials is an expense. Properly designed wheels and casters can reduce this expense.

Productivity

Wheels and casters affect the productivity of equipment and the people who use it. Selecting the proper wheel or caster insures maximum productivity, minimizes long term costs, and provides the greatest return on your investment.

Wheels are the heart of any piece of rolling equipment. Bearings make wheels go and thus affect production. Low grade tires and bearings do not provide profitable performance, especially when trying to adapt them to heavier loads or powered operation. Their use results in costly maintenance, equipment out of service and multiple manpower to move when not power drawn.

Safety and Ergonomics

The injury and health hazards involved in the use of manual equipment stems from the high draw bar pull, or resistance of equipment to movement. When possible select casters and wheels that eliminate, to a maximum degree, the possibility of injury and health complaints associated with excessive strain.

Keep the safety and well-being of your employees in mind when selecting a wheel or caster. In a manual application, a human being has to move the equipment. The larger the wheel diameter the easier a wheel rolls. The proper tire design and composition also impacts the performance and health of your employees.

Casters and wheels that are ergonomically sound reduce the potential for work related injuries. They lower absenteeism and increase the productivity and efficiency of workers. Ergonomically designed features reduce sources of physical stress and tension so that any employee can work comfortably without the risk of injury. One example would be swivel casters with a precision swivel bearing. This feature enables a swivel caster to turn more easily under load, reduces starting effort and fatigue, and allows a more consistent level of output. When you take safety and ergonomics into consideration, you reduce lost time due to accidents.

Floor Protection

Floors are expensive to repair or replace. Poor floors damage castered equipment, reduce productivity, and are hazardous to personnel. Selecting the most floor protective wheel appropriate for your application will protect good floors, and will reduce the rate of wear on floors already starting to deteriorate. Only wheels with a soft rubber tread are truly floor and cargo protective. These include PREMIUM, SUPER CUSHION, Conventional Moldon, Pneumatics, and Gray Rubber wheels. A common mistake is to think polyurethane wheels are floor protective. Although under load they are capable of some tire deflection, actual “tire give” is rarely noticeable. Most polyurethane wheels have a hardness comparable to “hard tread” wheels (phenolic, polyolefin, hard rubber), but are not as noisy. The “Jack Hammer” action of hard tread wheels is destructive to most floors with time. However, even metal wheels fill an important need when the operating environment or capacity prohibit the use of anything else.

Rollability

Remember that a human being has to move the load, so select the largest wheel your application will allow. Load capacity ratings do not take into account the effort required to manually move the load. Conventional moldon rubber wheels are not easy rolling. We recommend you reduce the weight to no more than 50% of their rated capacity if the load is to be moved manually on soft rubber wheels. Polyurethane and “hard tread” wheels are only easy rolling if you do not exceed the load capacity of the same size rubber wheel, and then only if the floors are smooth. They are not easy rolling when loaded to their full rated capacities. PREMIUM rubber wheels when loaded to full capacity can be moved manually. As long as your loads do not exceed the rated capacity of PREMIUM rubber, its selection means you will not have to give up the benefits of resiliency (floor and cargo protection) in order to get rollability.

Capacity

Selection should never be made on the basis of capacity alone. Capacity ratings on this website are based on intermittent use at a speed not exceeding 3 mph over smooth floors in a manual operation under ideal conditions. Your conditions are almost never ideal, so select a wheel or caster with much higher capacity than the weight you require. Always consult us first for a reduced capacity rating if the wheel or caster is to be used in a mechanically powered application. Capacity ratings are offered as an idea of what the wheel or caster will carry without failure. They are not absolute, but rather depend on the usage and service. Capacity ratings shown do not allow for shock loads, overloading, abuse, obstructions, or poor floors. Proper maintenance requires all bearings be relubricated on a regular schedule, and all bolts and nuts be kept tightened. Conditions of excessive temperature, dirt or other contaminants will reduce capacity and minimize performance. The temperature range shown for wheels in this catalog is the range of the wheel material. Operation near either end of the temperature range may require a substantial reduction in capacity, or cause a wheel to be unsuitable for the application.

Floor Obstructions and Operating Environment

Sometimes obstructions must be tolerated. Examples may include expansion joints which are not level, track, dock plate, or brick floors. There simply may not be an ideal solution. However, as a general rule, resilient wheels roll over floor obstructions better than hard tread wheels. Obstructions require selecting larger wheels and stronger casters than the application would require if the floors were smooth. Metal shavings can become imbedded in rubber and polyurethane tires. Steel plate can cut resilient tires, and chip or break hard tread wheels. Always keep floors clear of debris. Harmful substances or chemicals may require using special wheels or bearings. The bonding agent which holds rubber and polyurethane tires to their metal centers can be affected by exposure to some chemicals, impact, overloading, and the buildup of heat. Stainless Steel casters are made with 304 Stainless Steel which is rust resistant. In some severe applications over time Stainless Steel 304 may rust.

Cost/Value Analysis

Too often the purchase of wheels and casters is based on criteria far removed from the essential purpose – “Will they move the load smoothly and easily?” A piece of equipment purchased to carry and move a 2,000 lb. load is costly when it is loaded with only 1,000 lbs. in order to roll. Most people will load equipment only to a weight they can move easily and without injury. Equipment that requires two men to move it, when one should suffice, is also an expensive unit, regardless of acquisition cost.

Old style casters and wheels are usually built to a price, with no consideration of their investment value for profitable operation and pay back in productivity. Our products are competitively priced, but look beyond the price tag. Initial cost is a factor in a purchase decision, but it is only one factor.

Consider making a value analysis, it may bring out some other factors worthy of consideration. Value rate the product. A human being must push or pull castered equipment. Ease of rolling and wheel life are the two important elements of an efficient and economical manual operation. Sometimes a certain caster or wheel may not be the least expensive choice if you are looking at only the initial cost of acquisition. However, if it is the right caster or wheel for a particular application, the cost will be commensurate with the value and the pay back.

Ask yourself to what extent will a caster or wheel require maintenance? The cost of acquiring a product should be weighed against the cost of keeping it in operating condition. Bearings and their service generally are the largest factor in maintenance. The cost of systematic lubrication and replacement can be a drain on profits; if one is neglected, the other increases.

Will the caster or wheel further dependable operation? With an easier rolling wheel and easier turning swivel, employees tire less, there are fewer accidents and productivity increases.

Our Staff can give you valuable assistance in the selection of the right combination of wheels and casters for your needs. They have a deep understanding and extensive experience with heavy-duty casters.