Dual Wheel and Ergonomic Casters: A Comprehensive Guide

Ergonomic caster wheels with a crown-shaped or convex tread profile are designed to require less effort to change direction compared to flat-tread wheels. This is because the crown shape causes the wheel to pivot around a central point, which reduces friction and makes steering or turning smoother.

Here’s why crown-shaped caster wheels are advantageous:

- Reduced Friction: The highest point of the crown carries most of the load, resulting in less contact area with the ground. This reduces friction and makes it easier to initiate and maintain motion. This helps crown-tread wheels roll easier over carpet as well.

- Better Steering Control: When you want to change direction, the wheel naturally tends to rotate around the high point of the crown, facilitating steering. This is particularly useful in applications where precise control and maneuverability are required.

- Less Resistance: With less friction and resistance, less force is required to turn or steer the wheel, which can reduce operator fatigue and make equipment more efficient.

Crown-shaped wheels are commonly used in various applications, including office chairs, shopping carts, bellman and luggage carts, and industrial equipment, to improve maneuverability and ease of use.

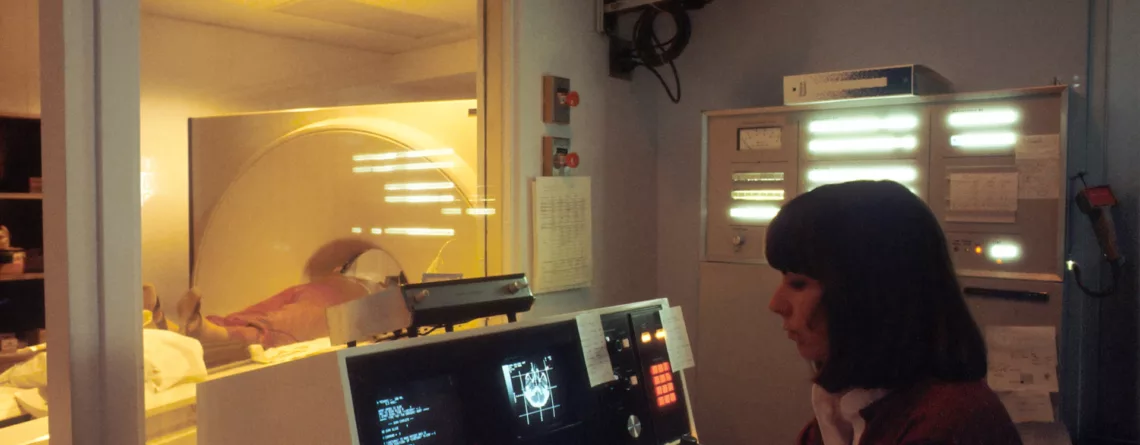

What’s the difference between ergonomic and dual wheel?

Another kind of ergonomic caster are dual-wheel casters. Dual wheel casters, also known as twin wheel casters, offer advantages when it comes to changing direction compared to single-wheel casters. This is primarily due to the differential action of the wheels as they rotate in opposite directions. Here’s how this works:

- Improved Stability: Dual-wheel casters provide better stability because they distribute the weight load over a larger area than a single-wheel caster. This added stability helps prevent tipping and allows for smoother movement.

- Differential Action: When you change the direction of a dual-wheel caster, the wheels rotate in opposite directions. This differential action minimizes the resistance and effort required to turn or pivot the caster, making it easier to change direction. The wheels effectively counteract each other’s resistance, resulting in a smoother swivel.

- Maneuverability: Dual-wheel casters are often used in applications where precise maneuverability is crucial, such as office chairs, furniture, and equipment that needs to navigate tight spaces.

What kind of Caster do I pick?

Overall, dual-wheel casters are preferred in situations where ease of direction change, stability, and smooth movement are important considerations. They excel in providing better control and maneuverability compared to single-wheel casters.

Caster City also manufactures heavy-duty dual wheel casters for the most arduous industrial applications. If you’d like a specialized quote, call us at 800-501-3808